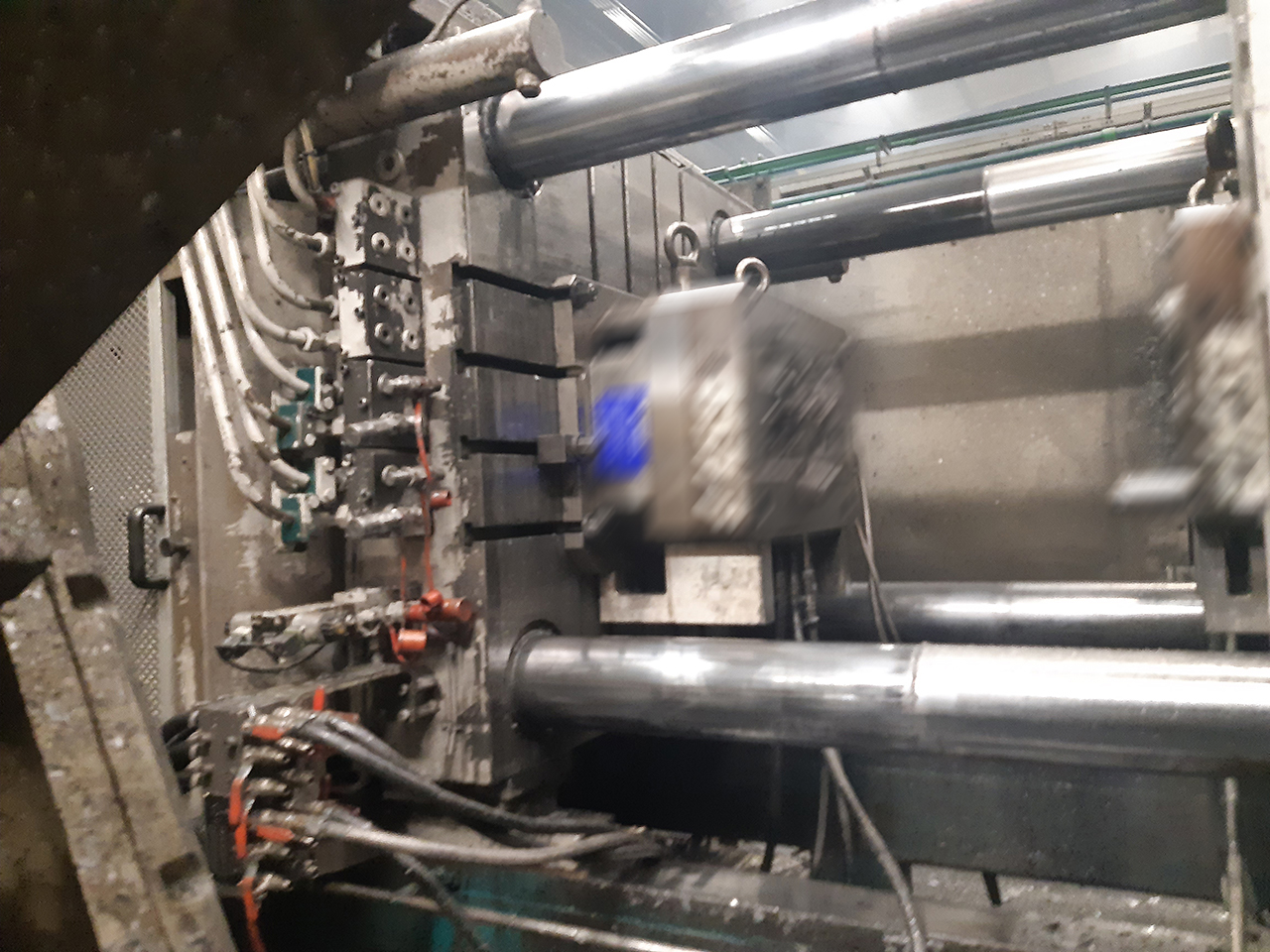

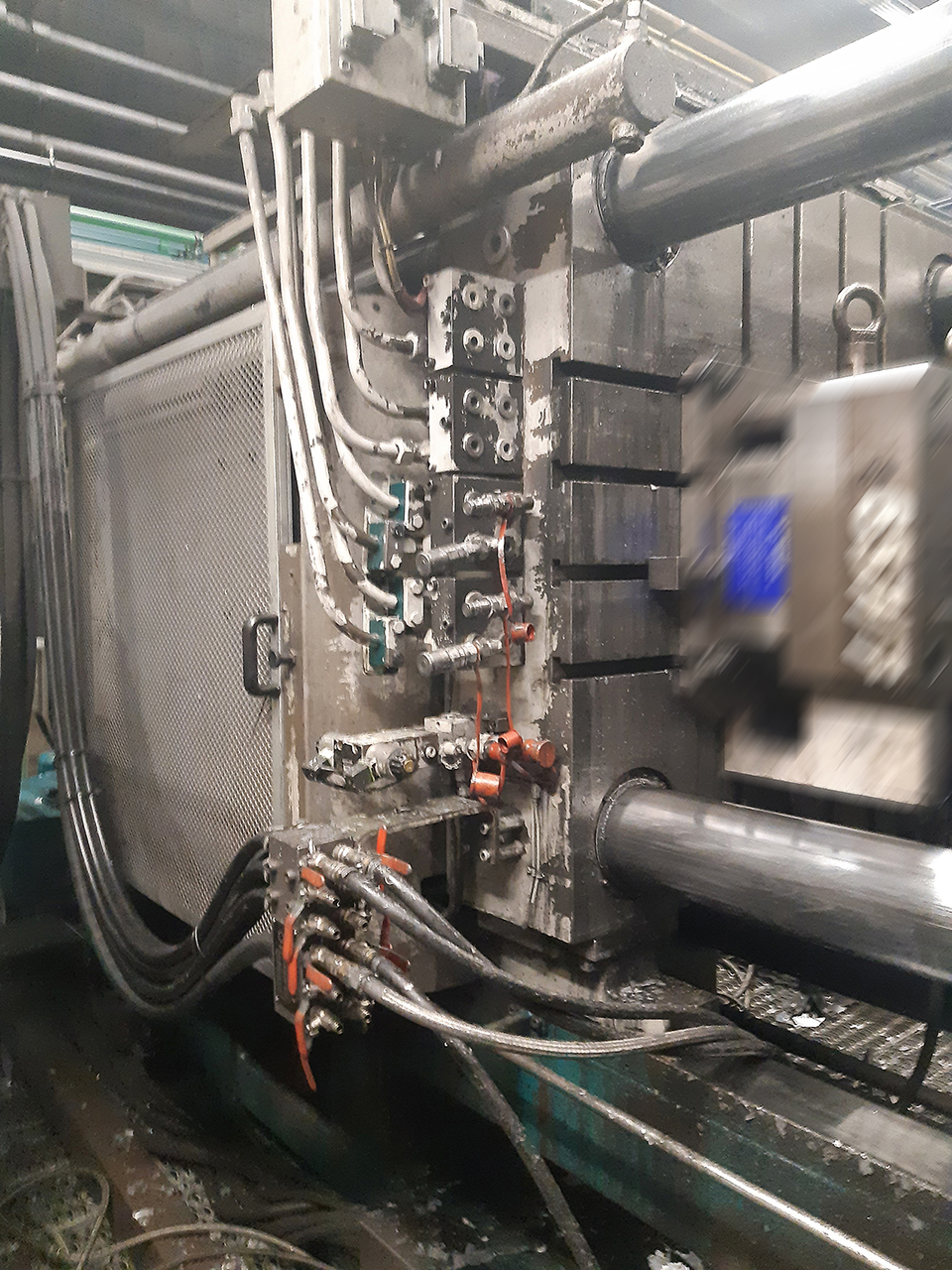

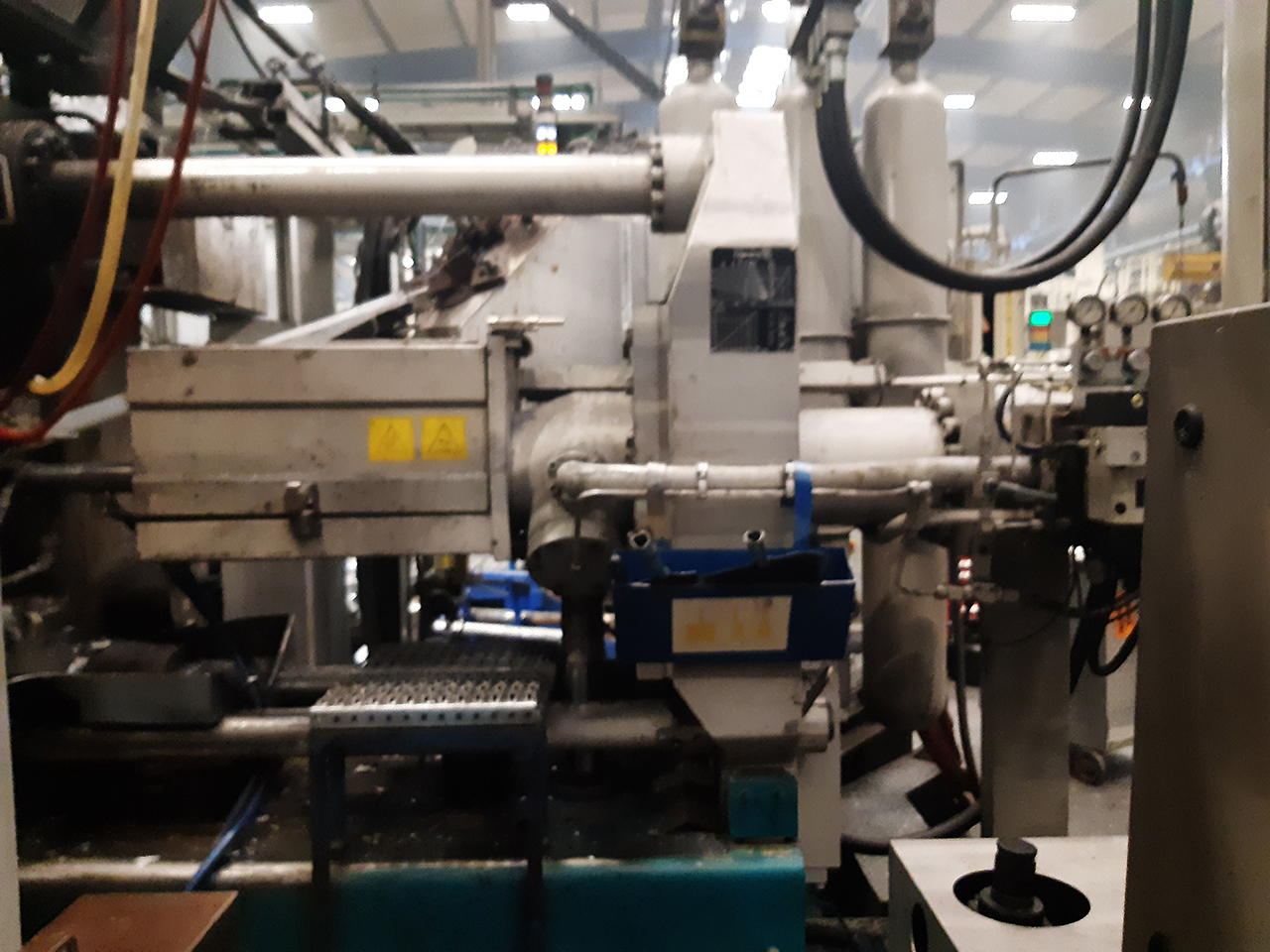

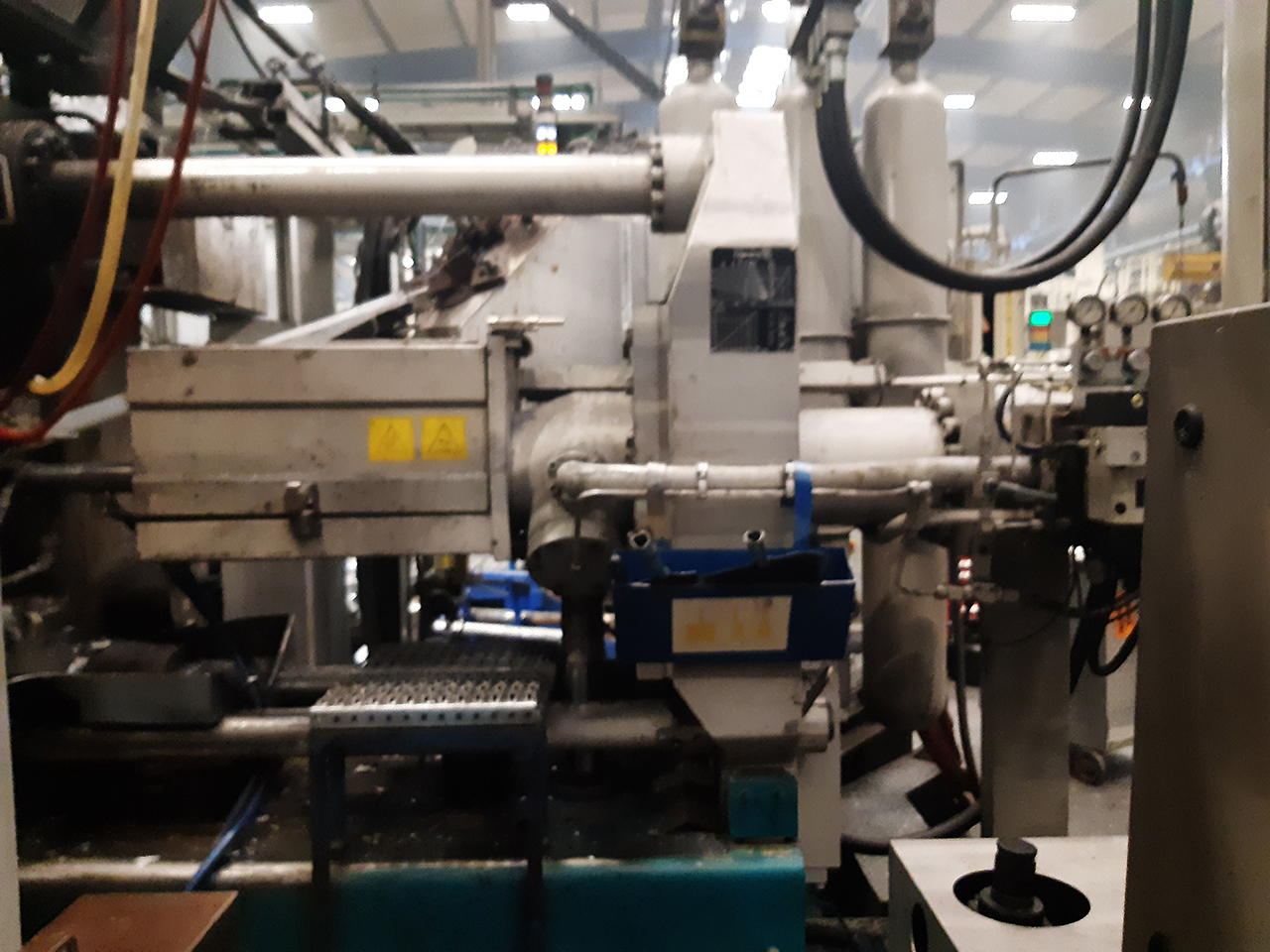

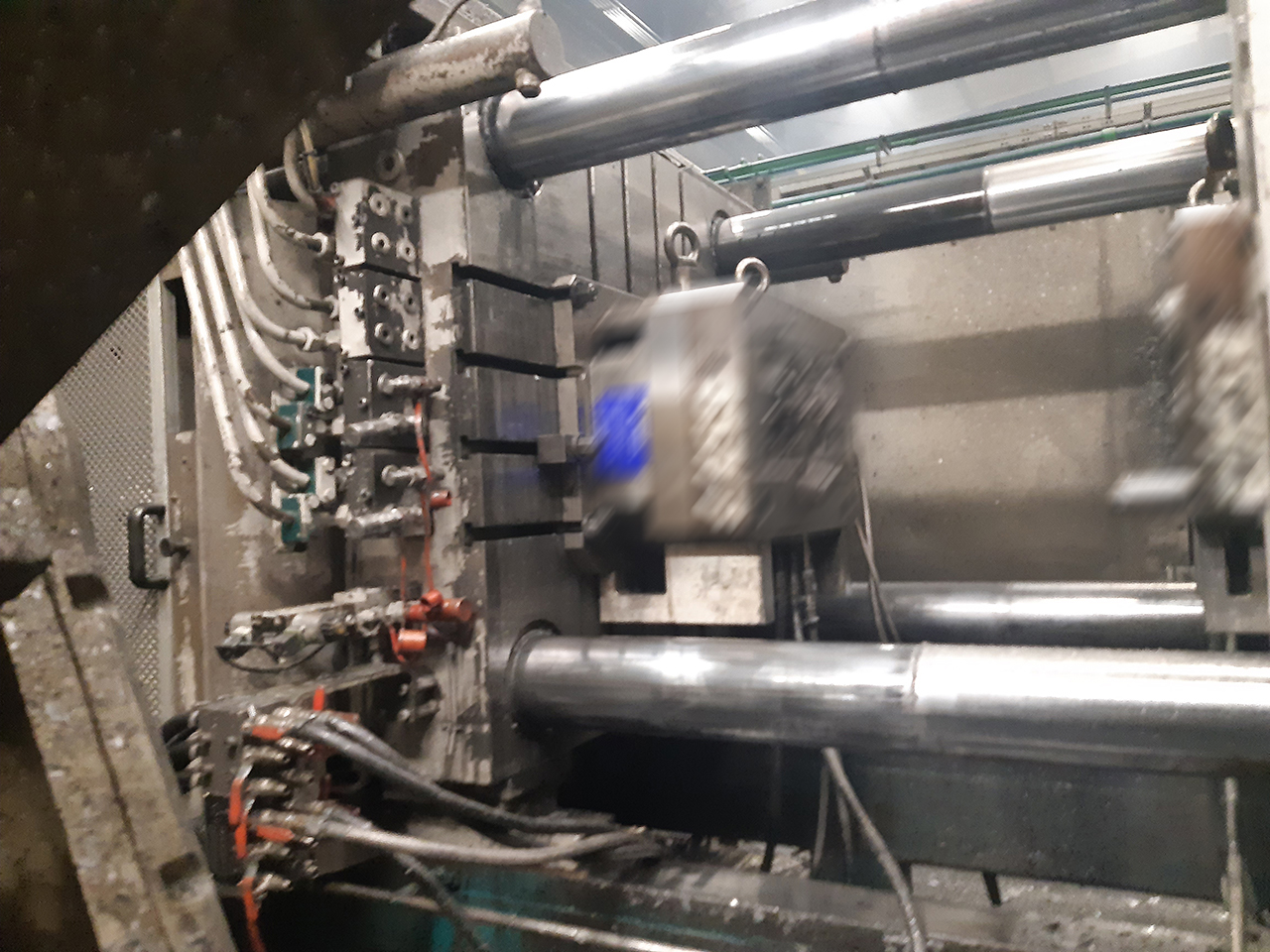

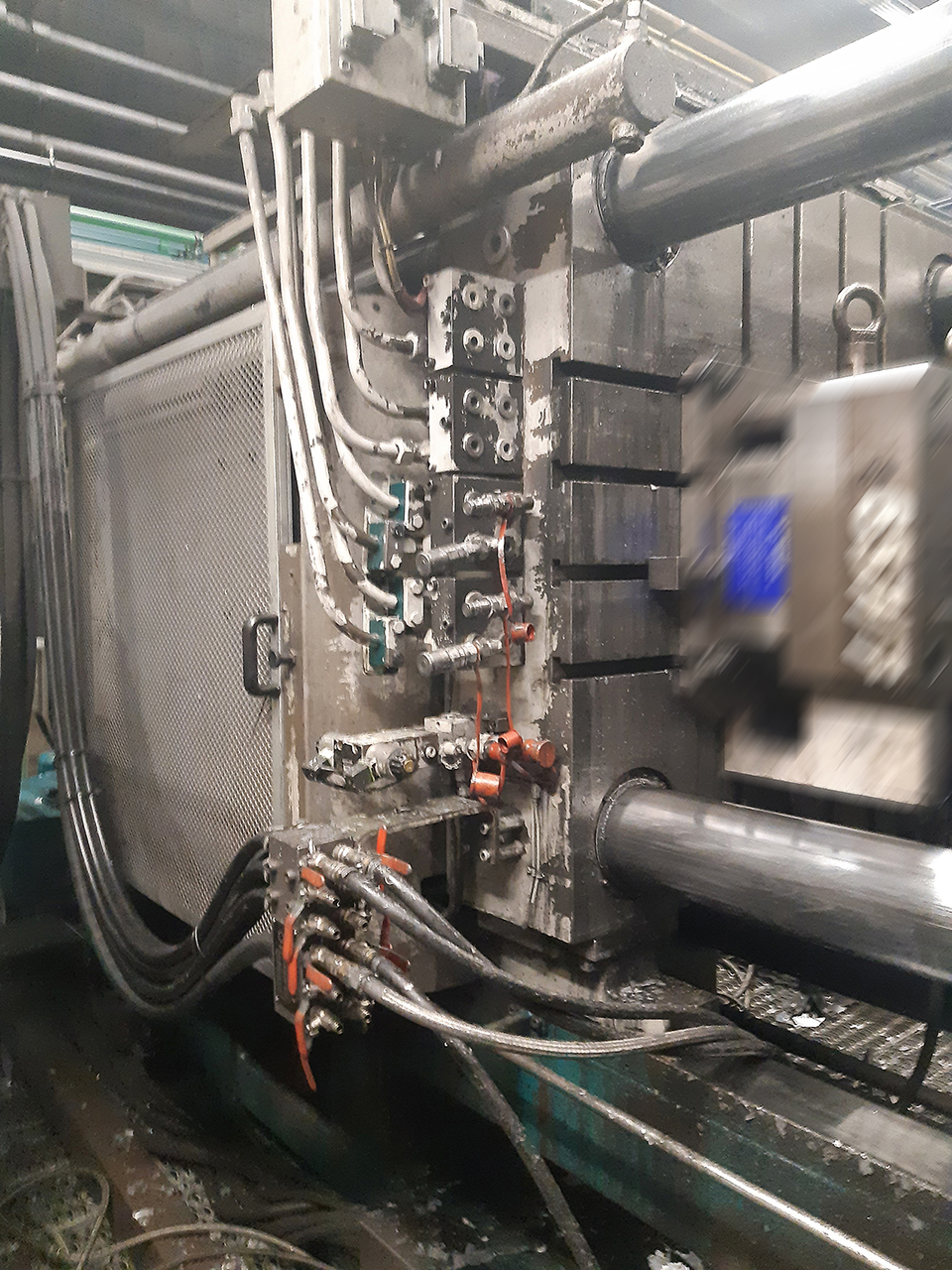

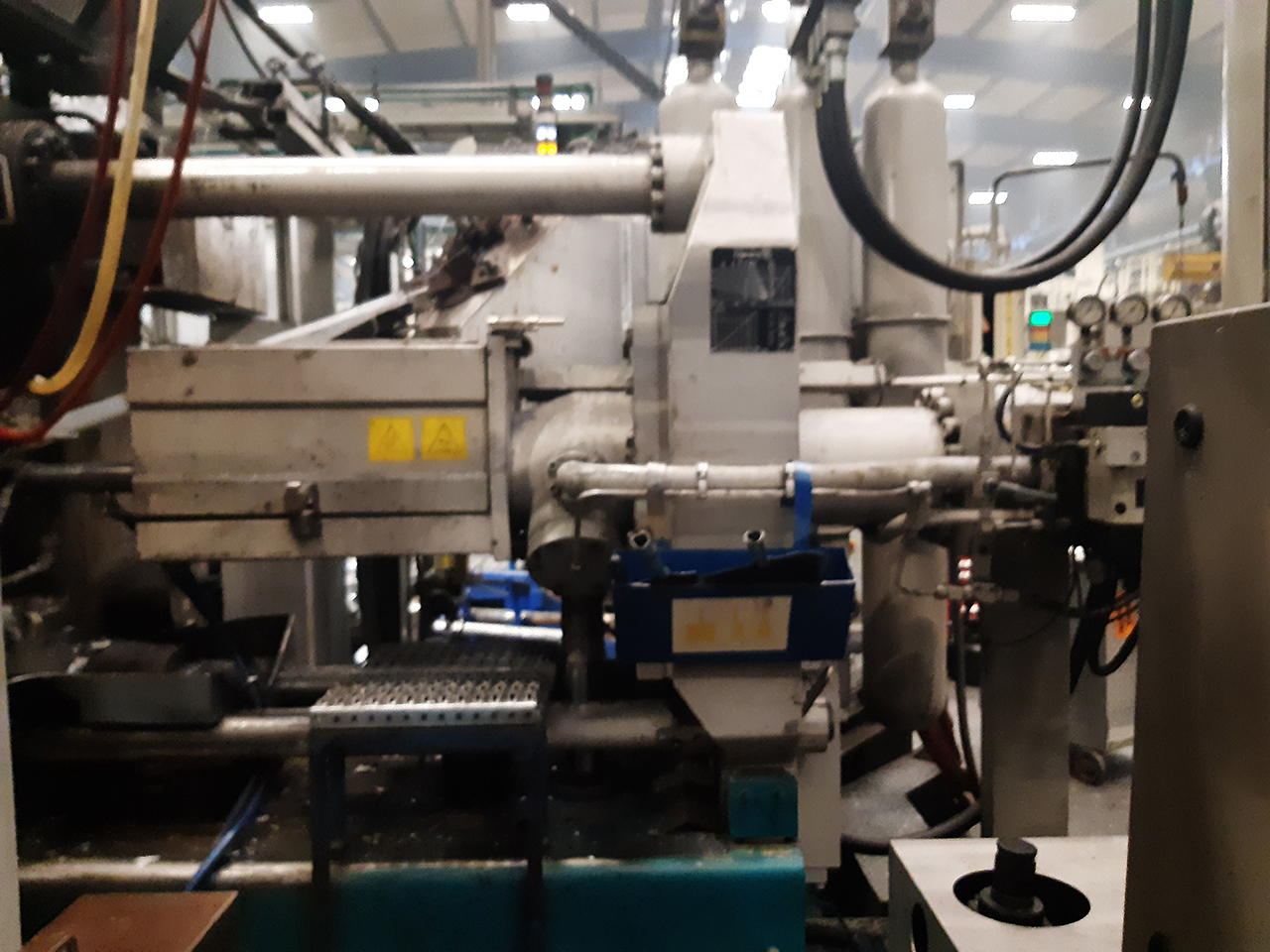

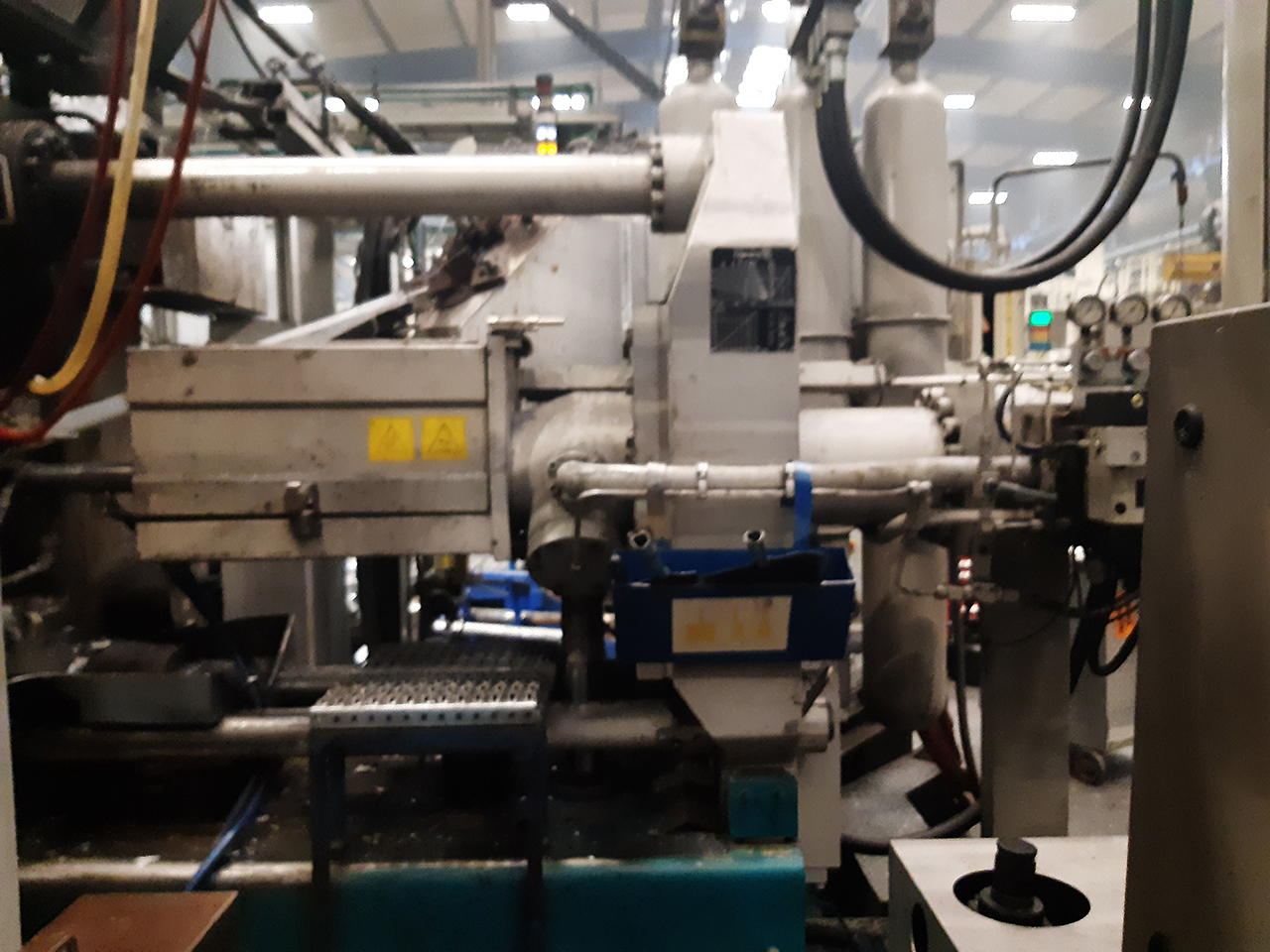

Buhler H 630 B cold chamber die casting machine KK1627, used

Product information "Buhler H 630 B cold chamber die casting machine KK1627, used"

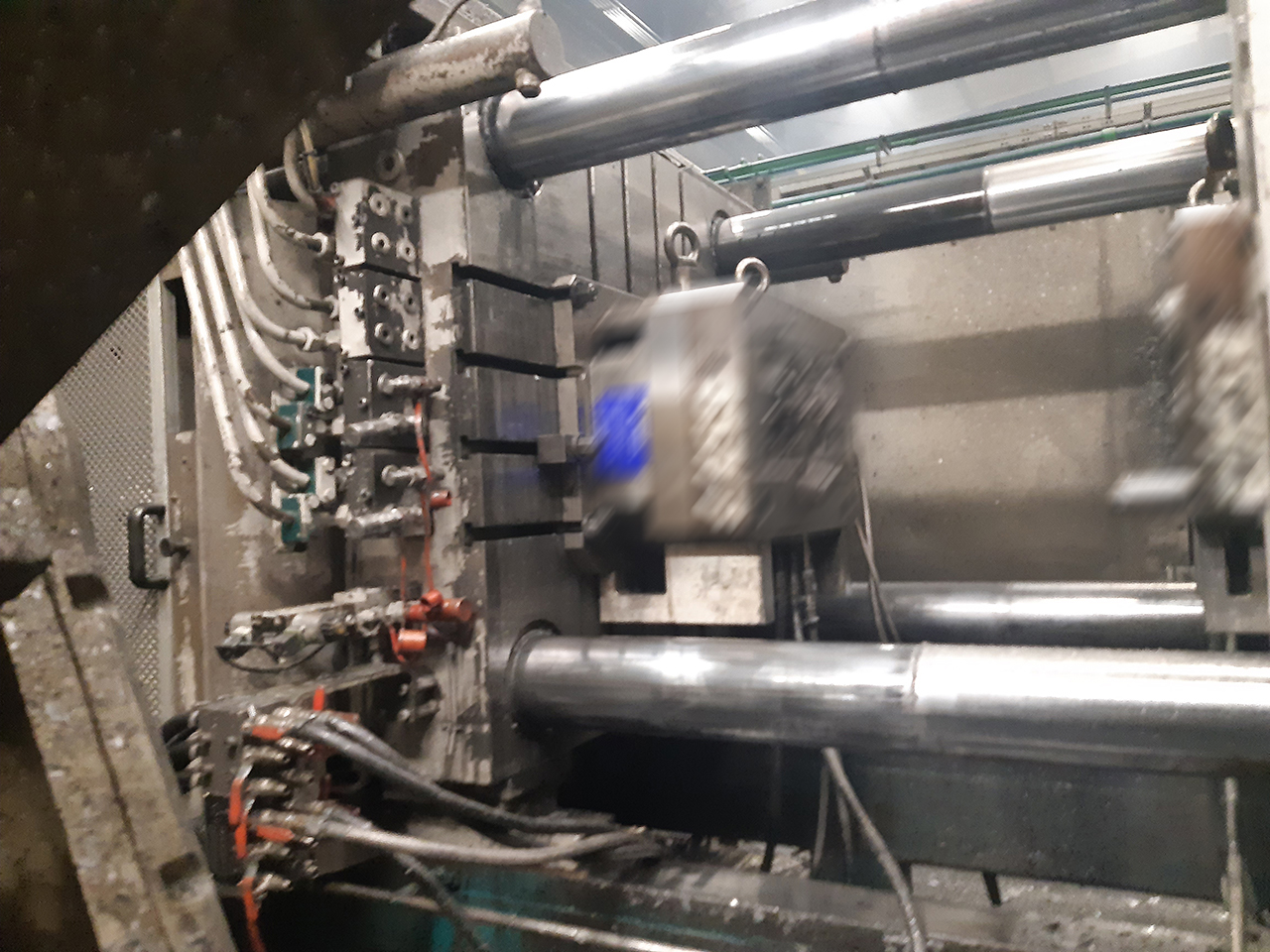

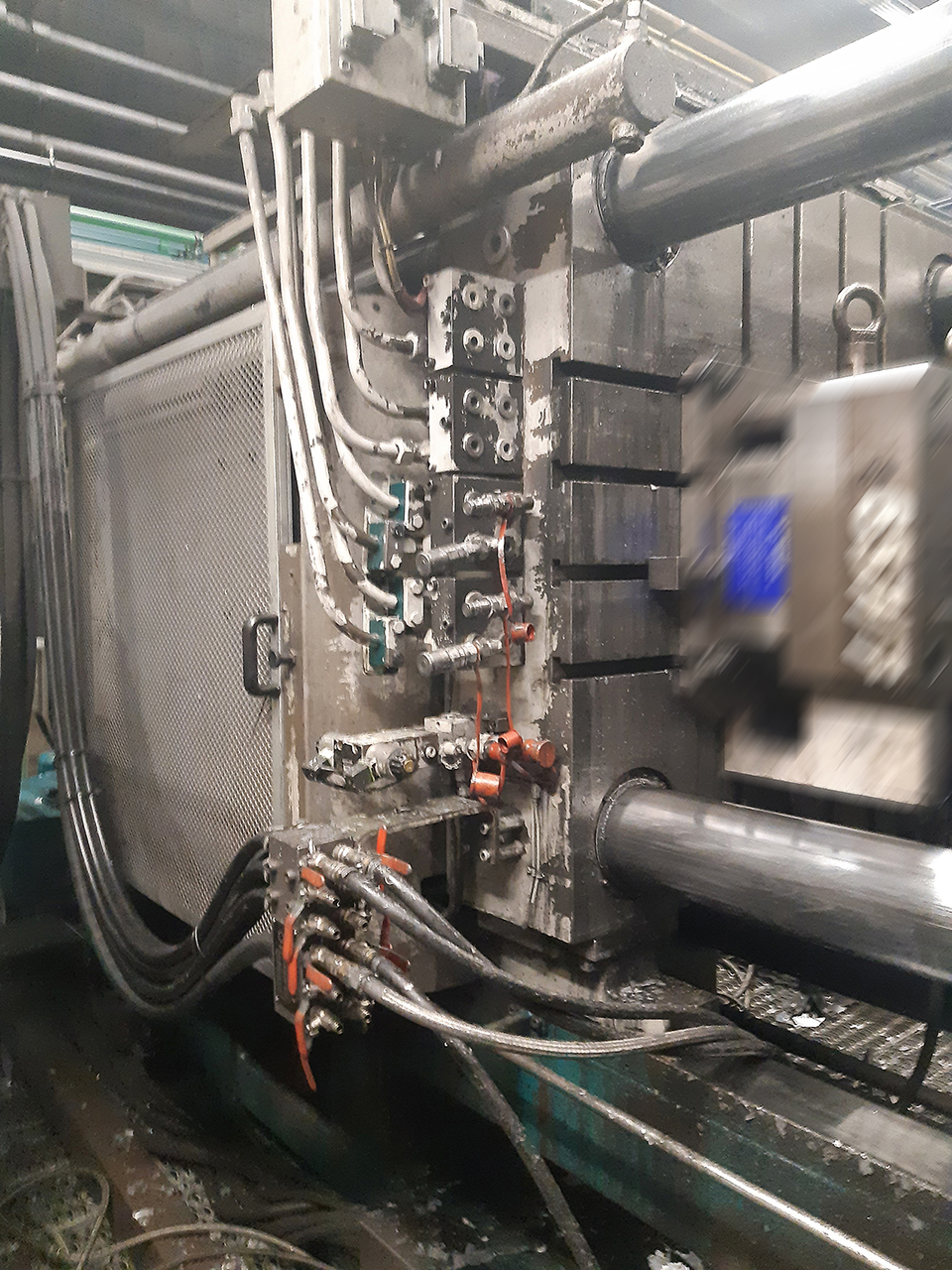

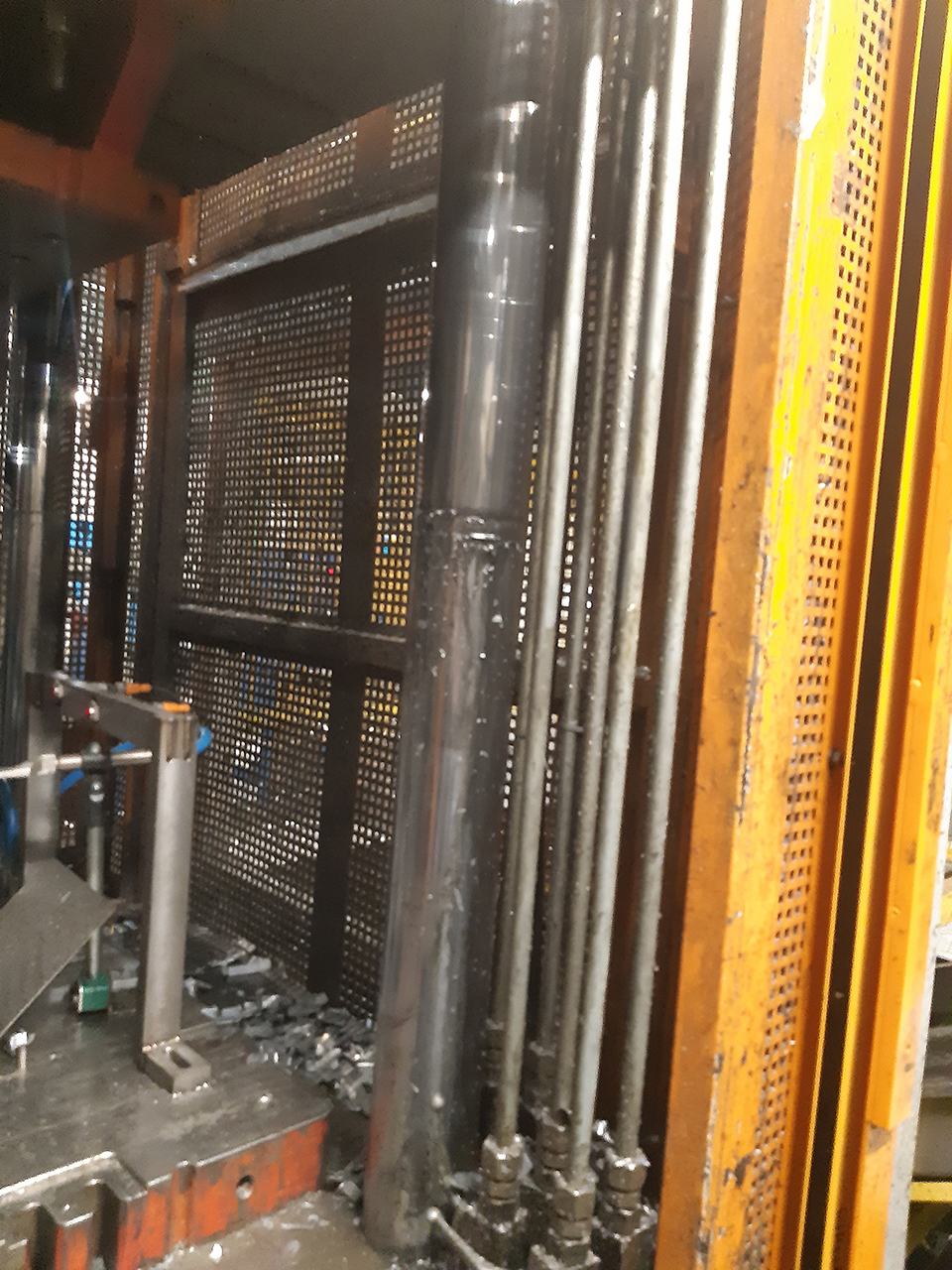

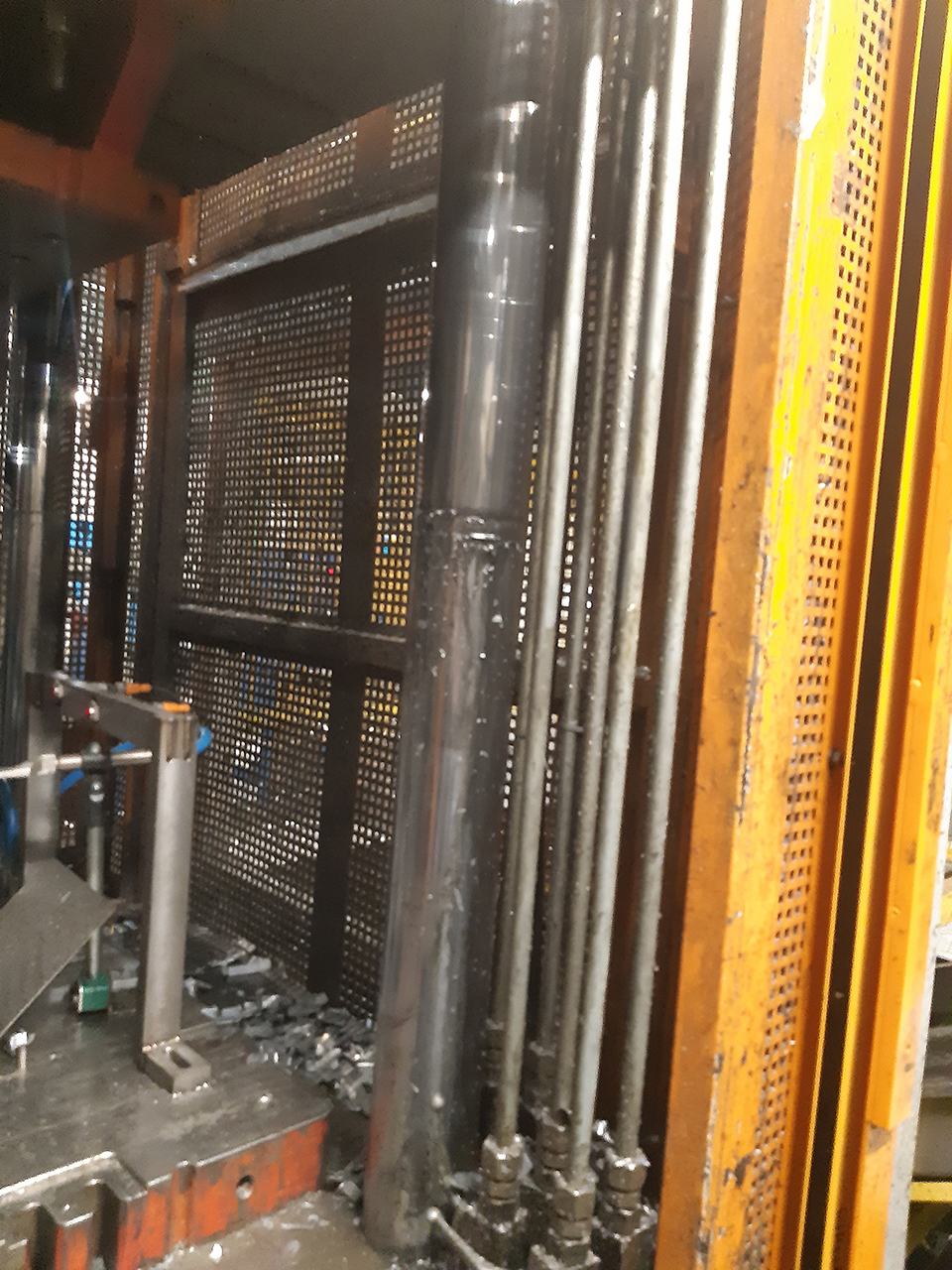

| Die Casting Machine | |

| Manufacturer | Buhler |

| Model | H 630 B |

| Locking Force | 6300 kN |

| Year of Manufacture | |

| Comments | overhauled 2014 in Bühler Brescia |

Accessories

| Dosing furnace | available |

| Manufacturer | StrikoWestofen |

| Model | W 650 SL ProDos XP |

| Year | 2008 |

| Heating | electrical |

| Comments |

| Metal loader | not available |

| Manufacturer | |

| Model | |

| Year |

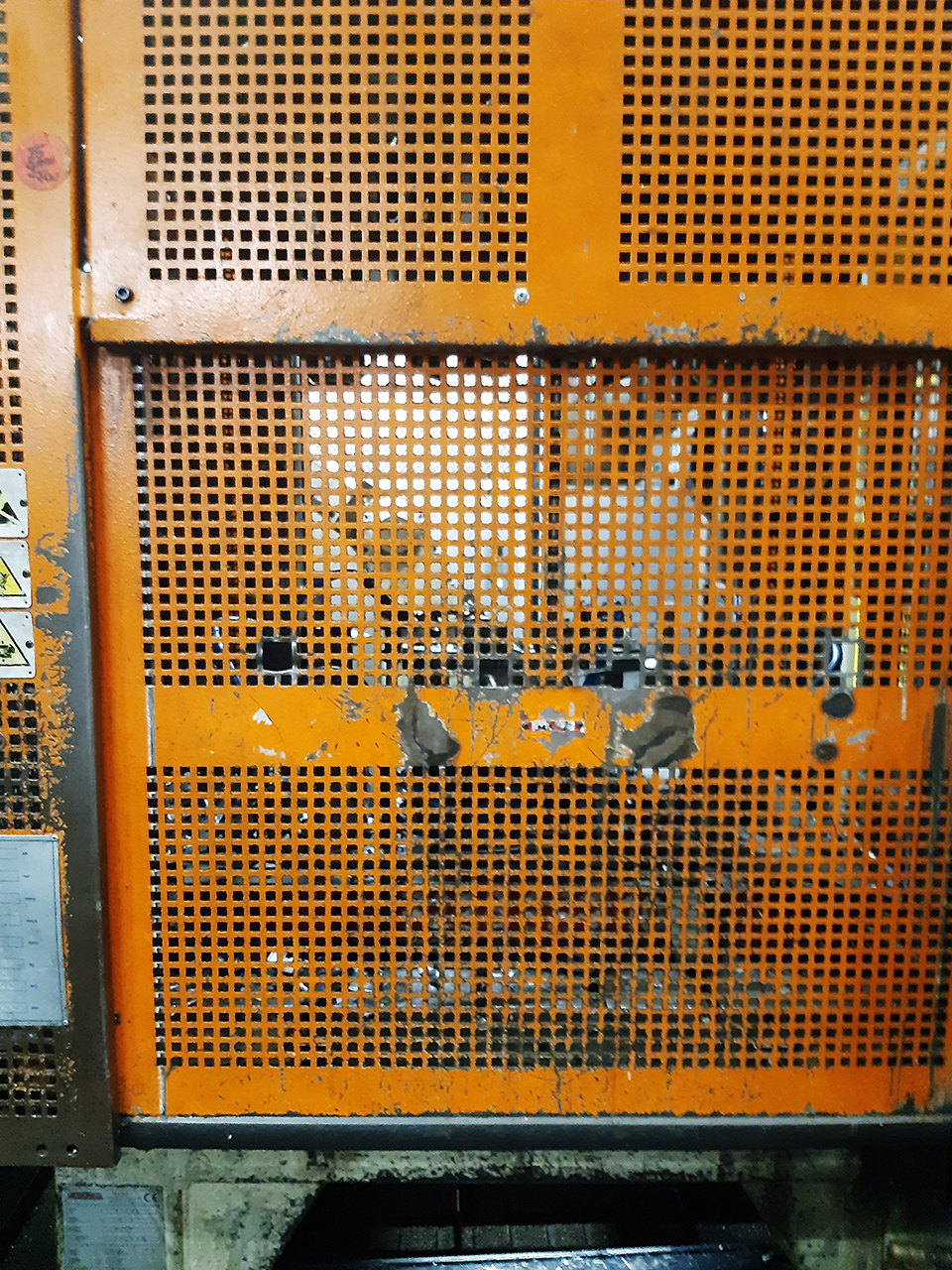

| Spraying machine | available |

| Manufacturer | Wollin |

| Model | PSM 2 F |

| Year | 2001 |

| Comments | spraying tank |

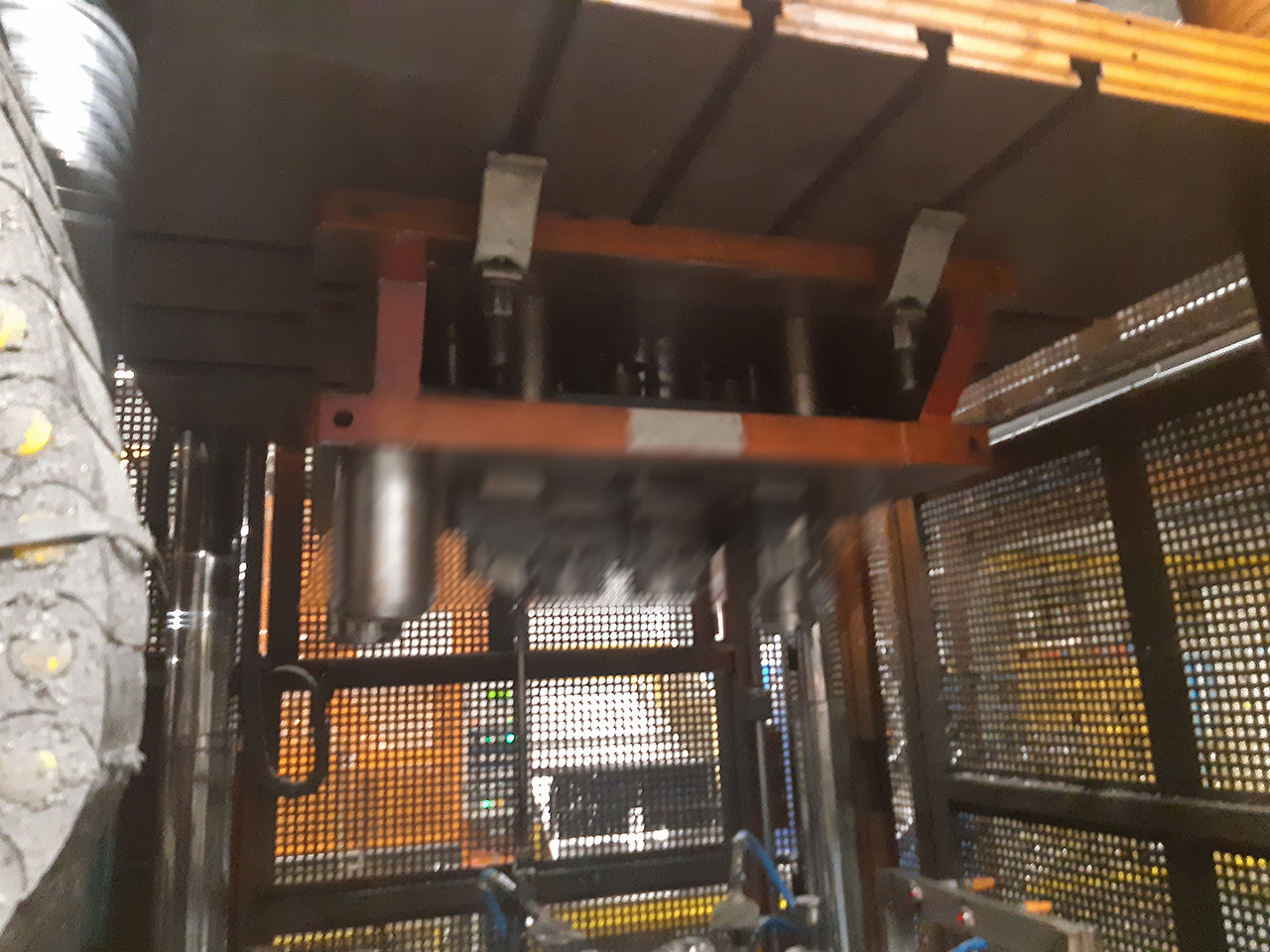

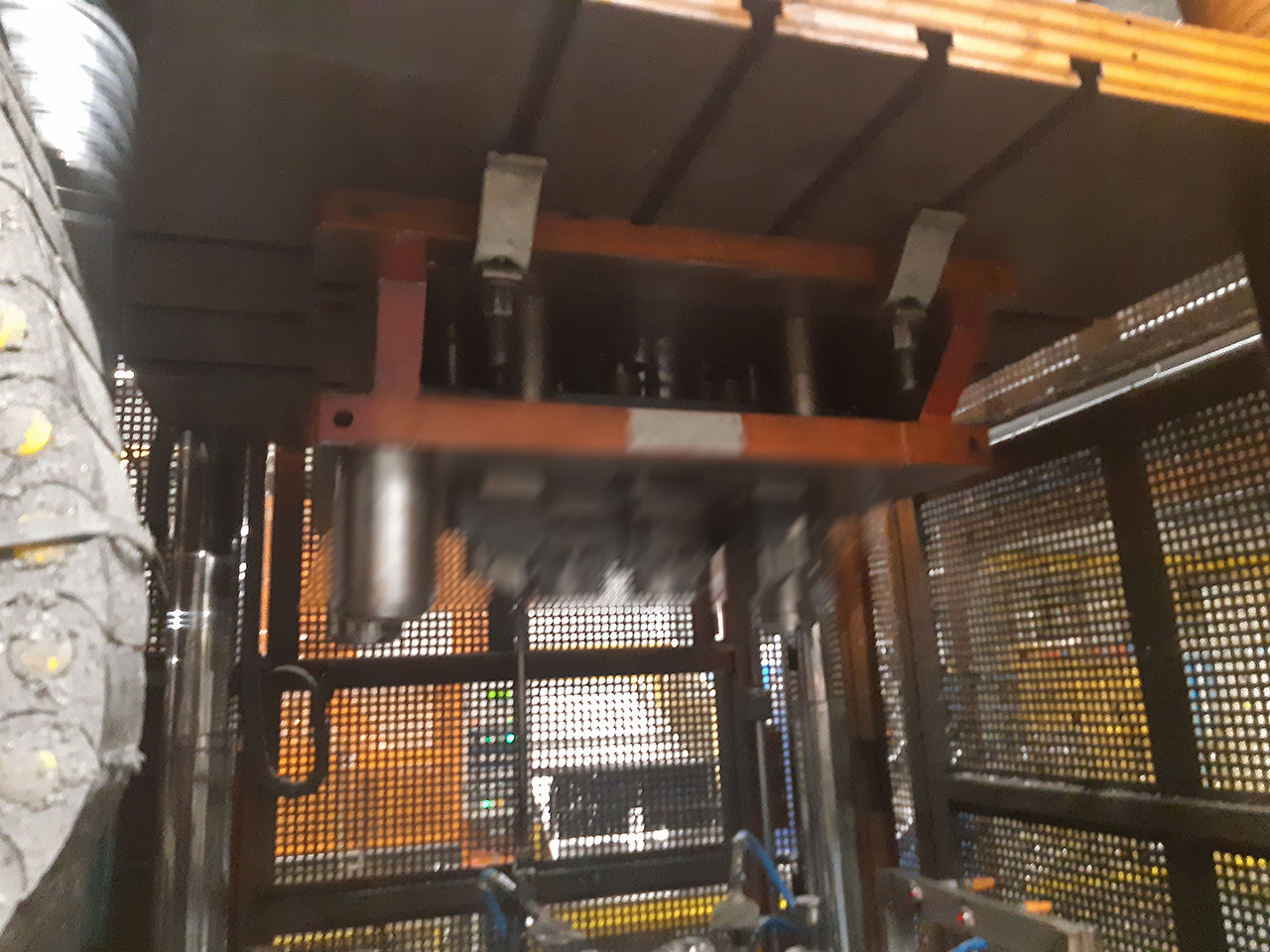

| Foundry Robot |

available |

| Manufacturer | Kawasaki |

| Model | FS 020-540P (v.c 540P |

| Year | 2007 |

| Comments | pick and place robot |

| Conveyor belts | not available |

| Manufacturer | |

| Model | |

| Year |

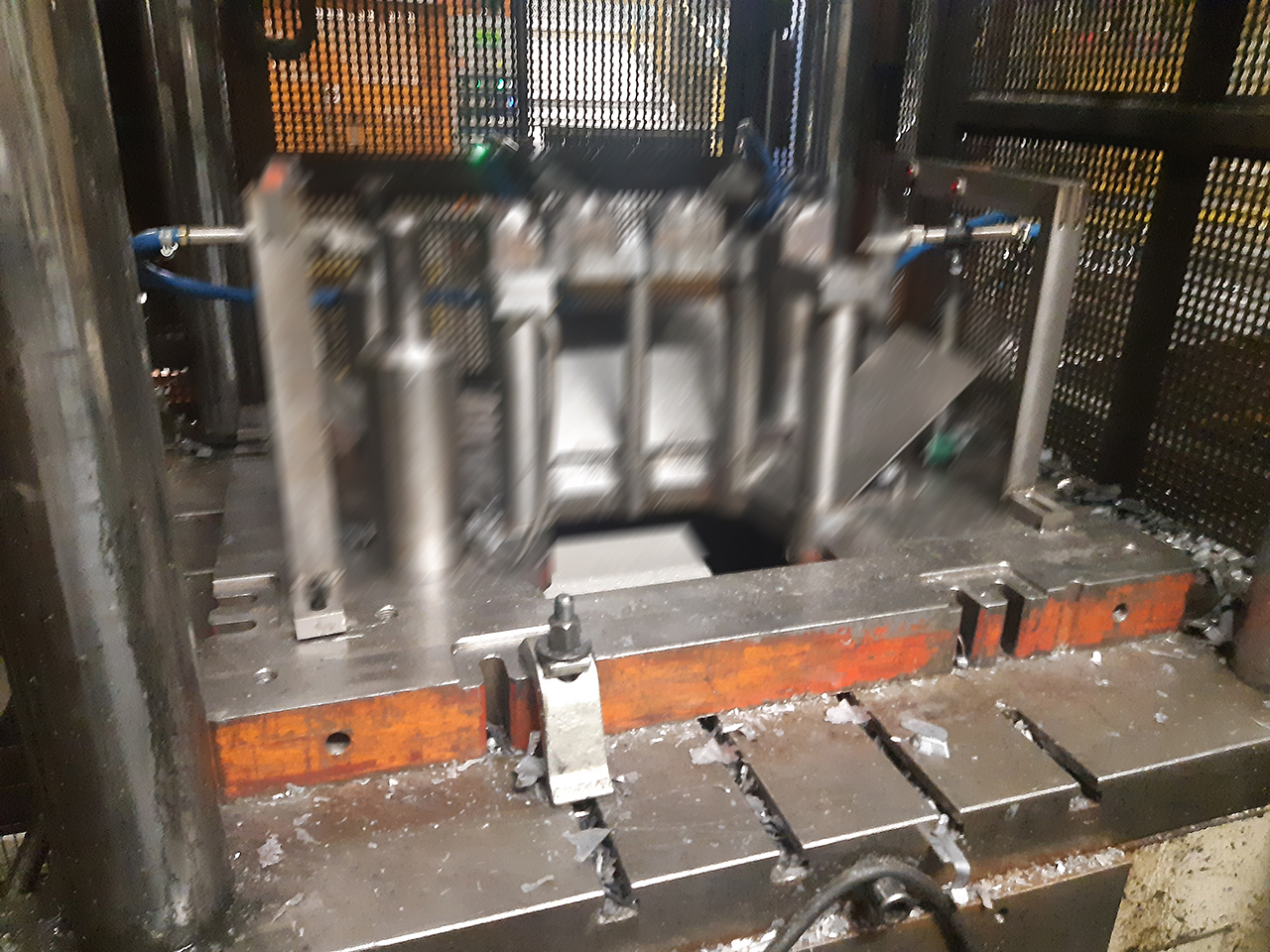

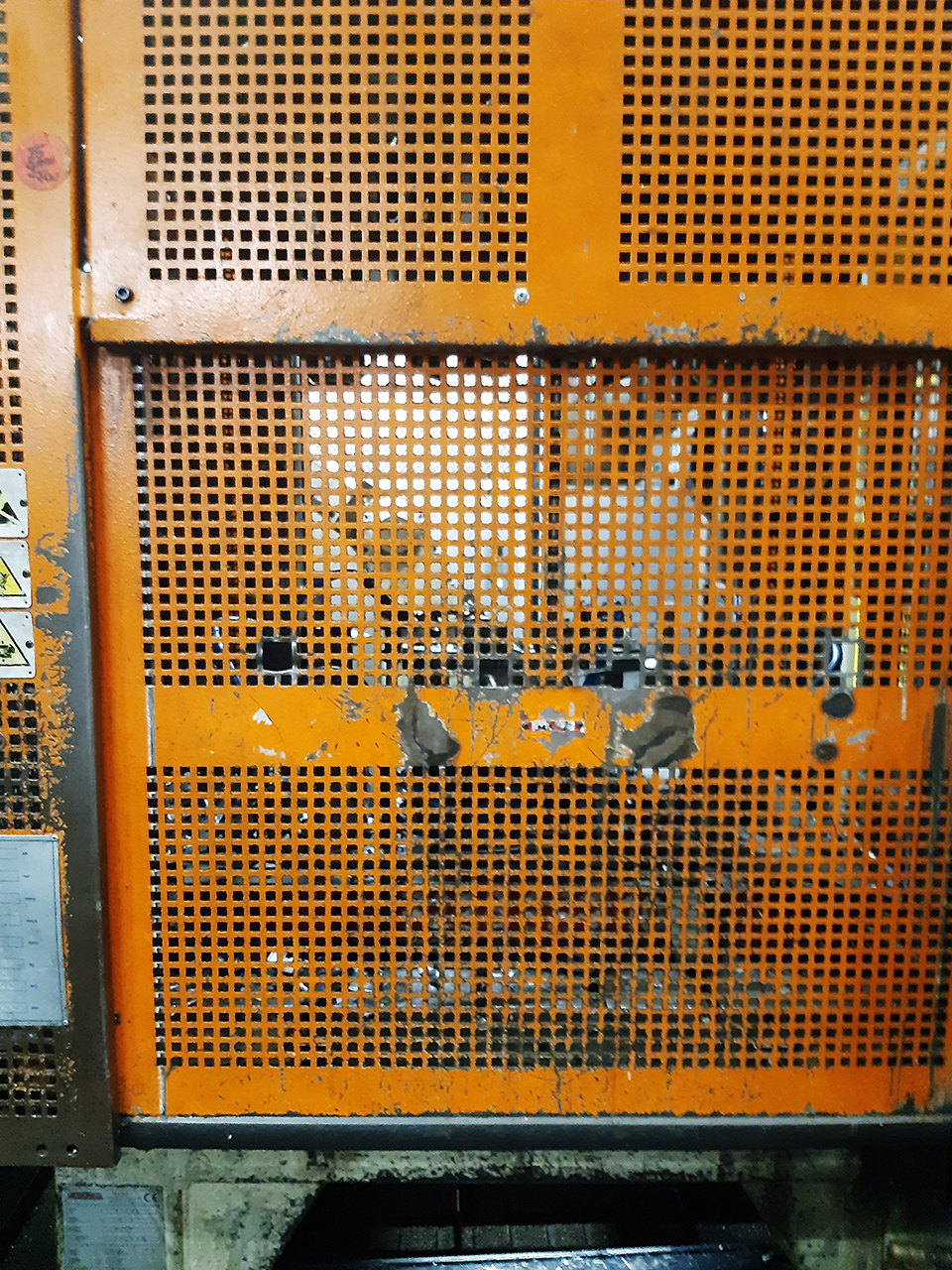

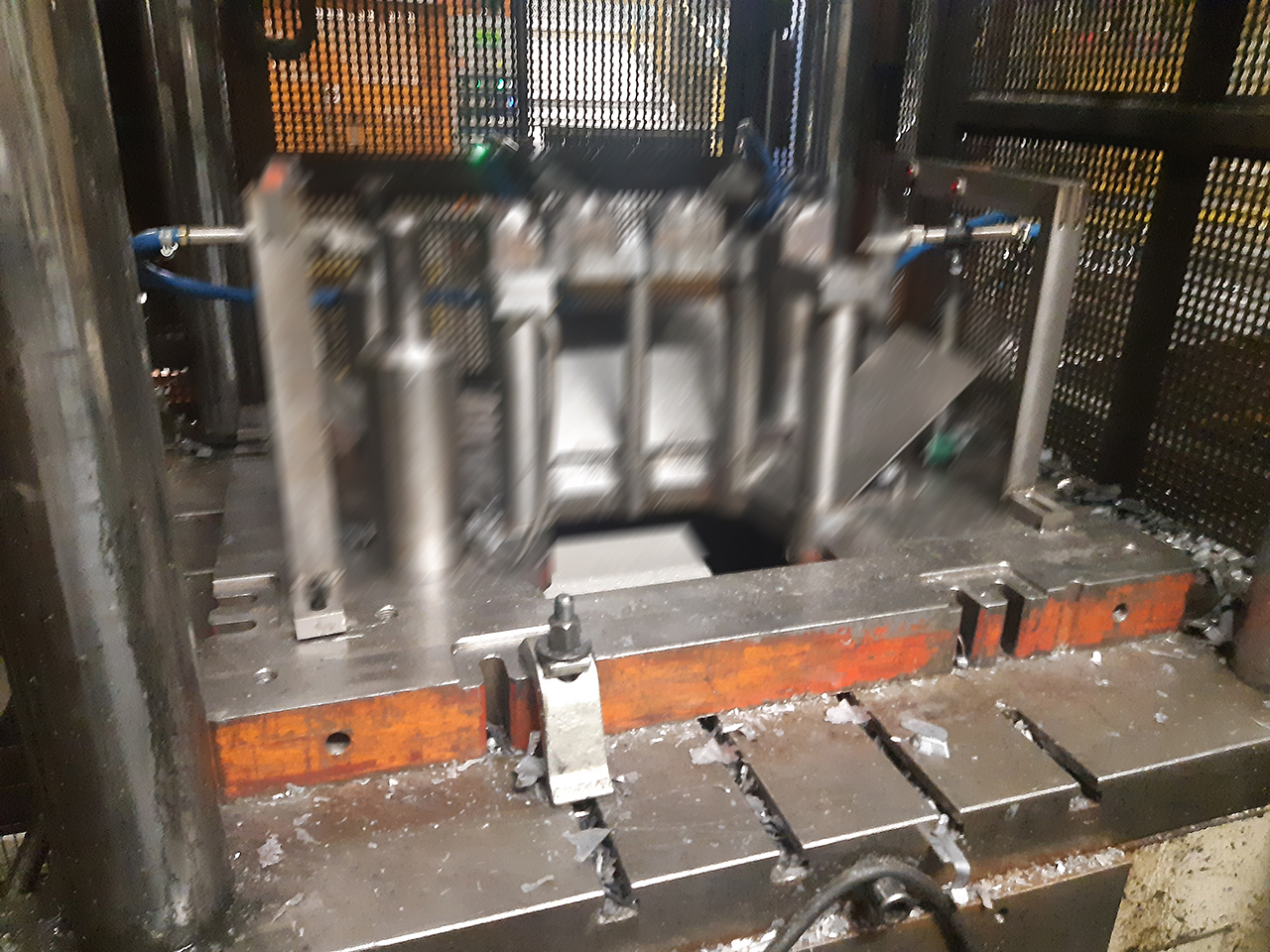

| Trimming press | available |

| Manufacturer | Diesse |

| Model | T 35 NG |

| Year | 2007 |

| Comments | with sliding tabel |

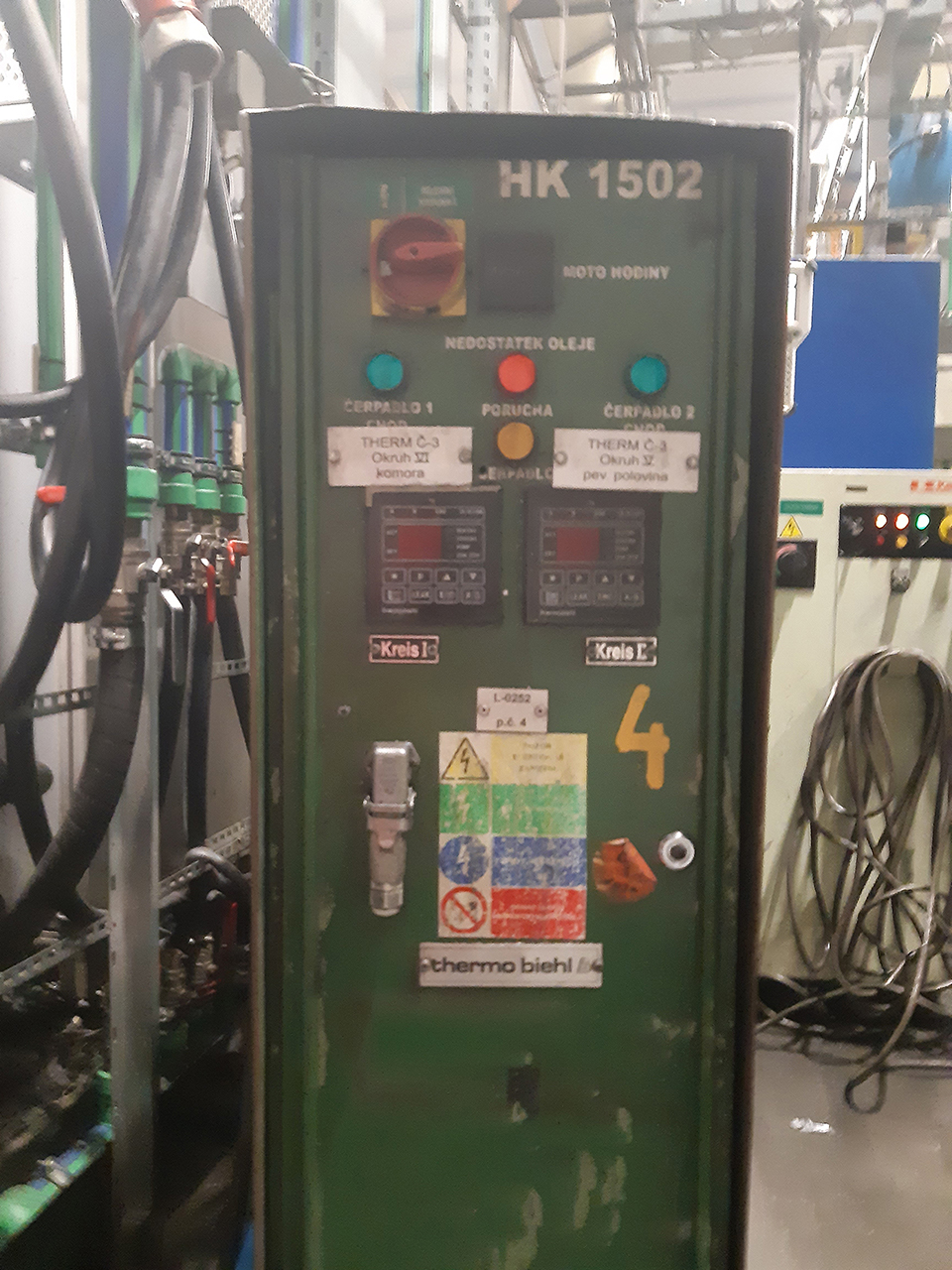

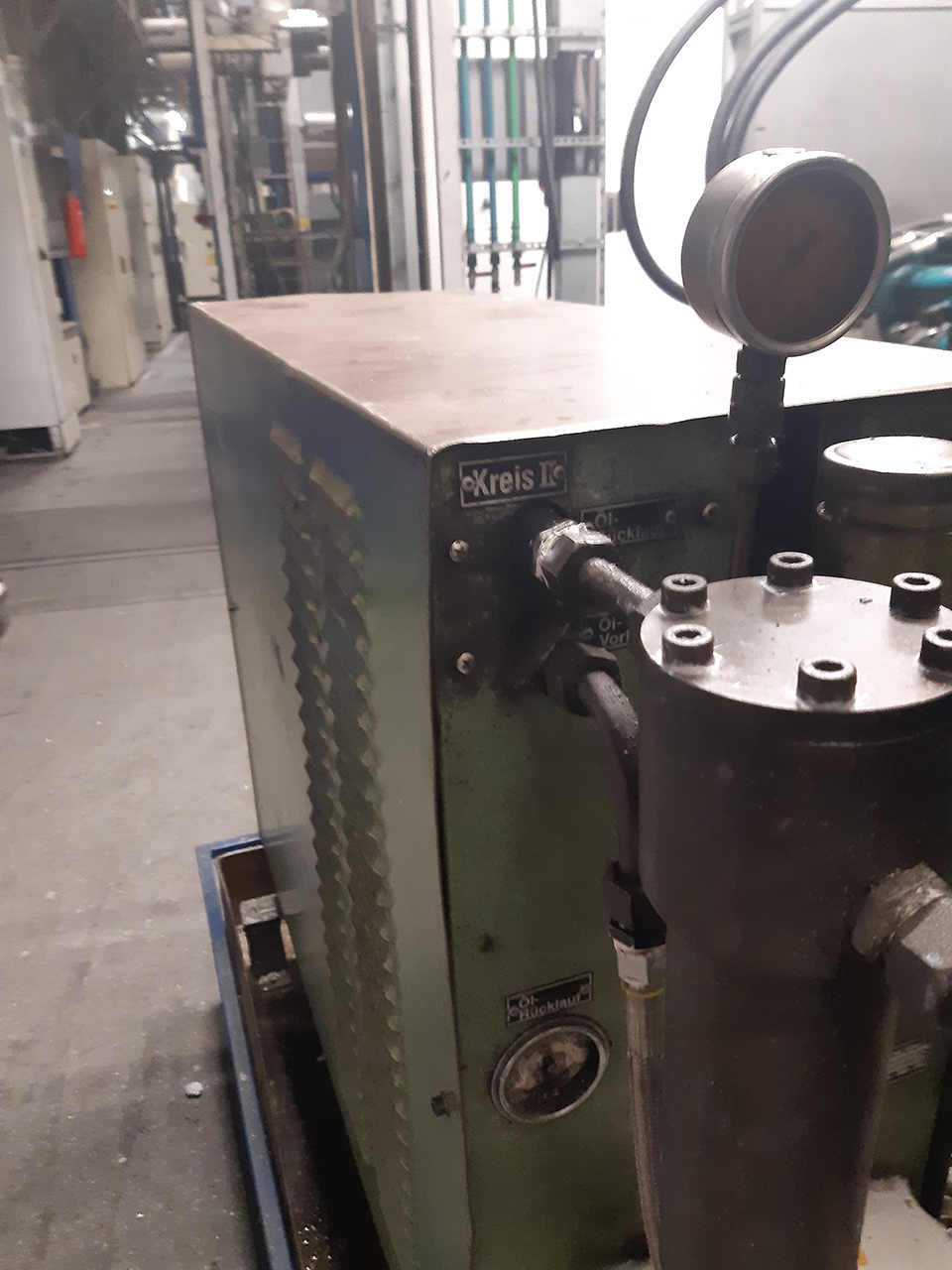

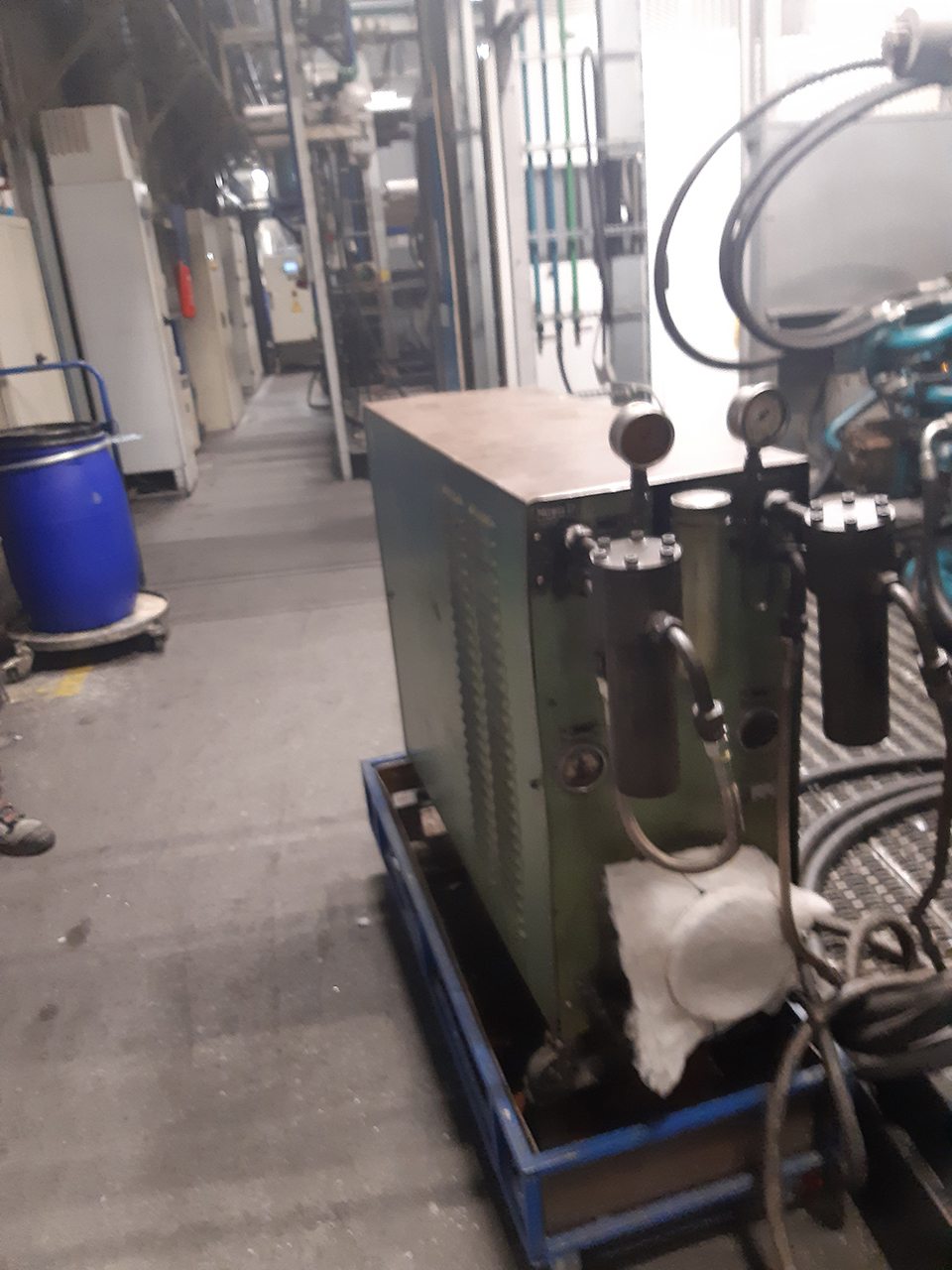

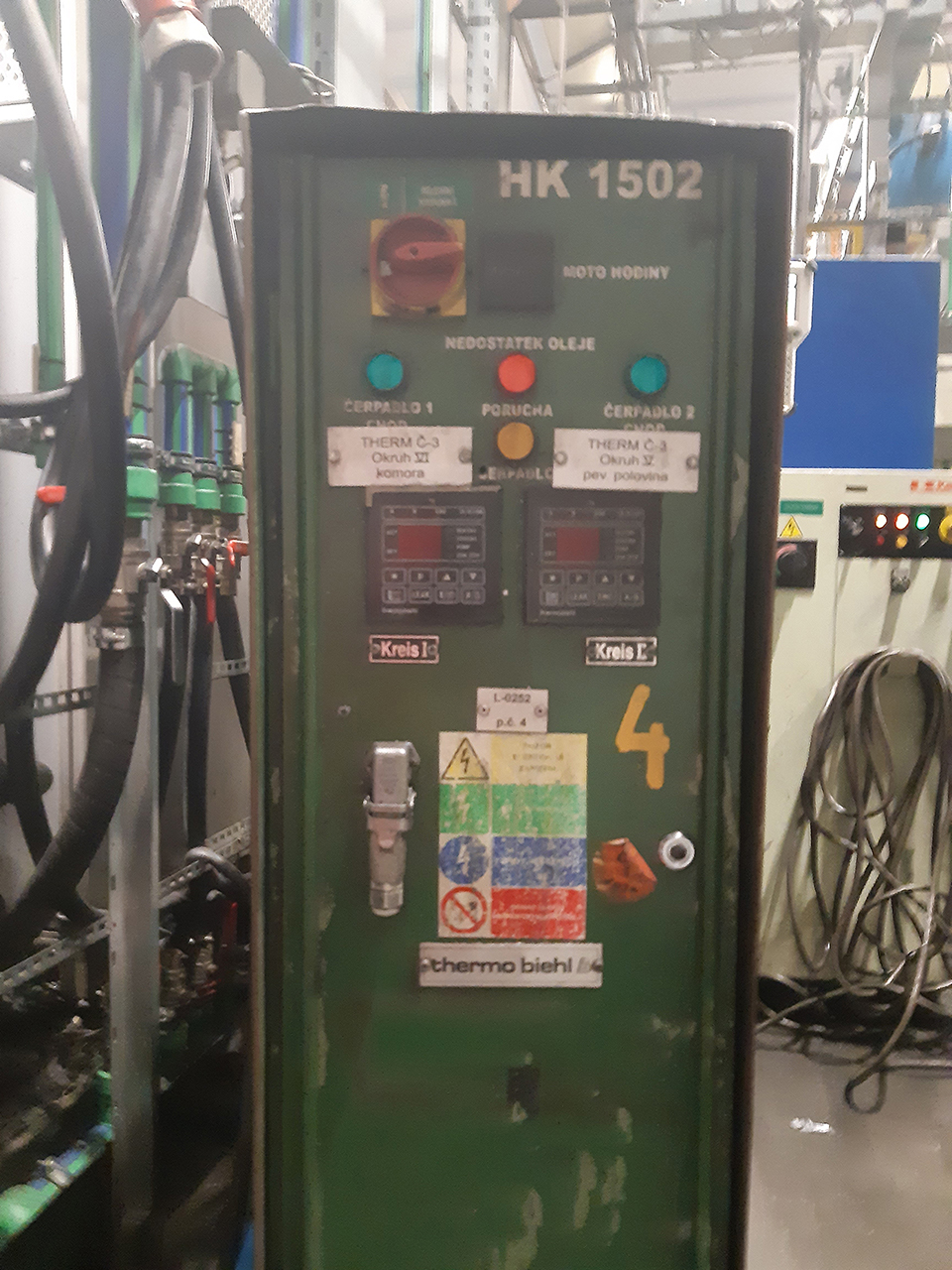

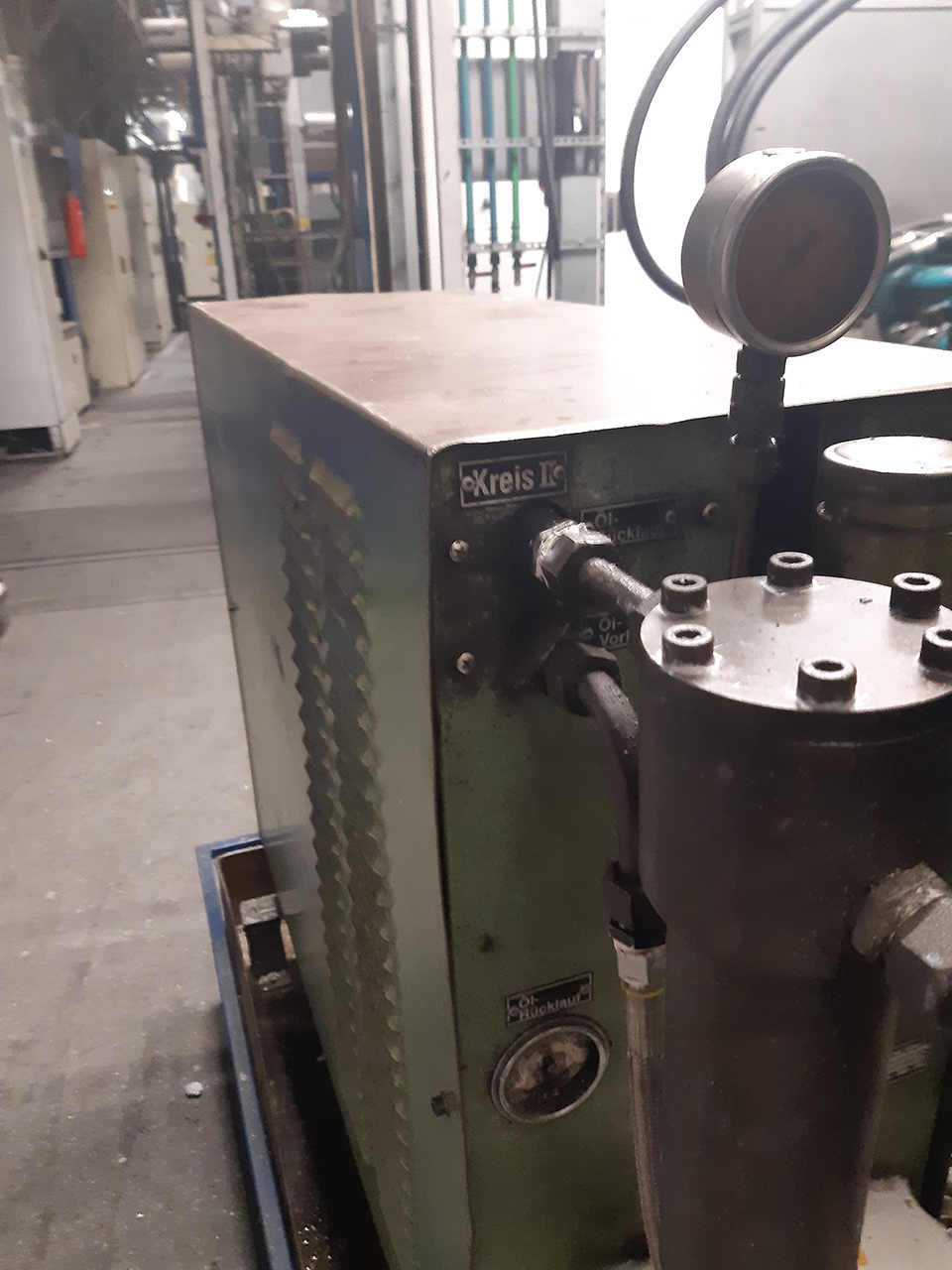

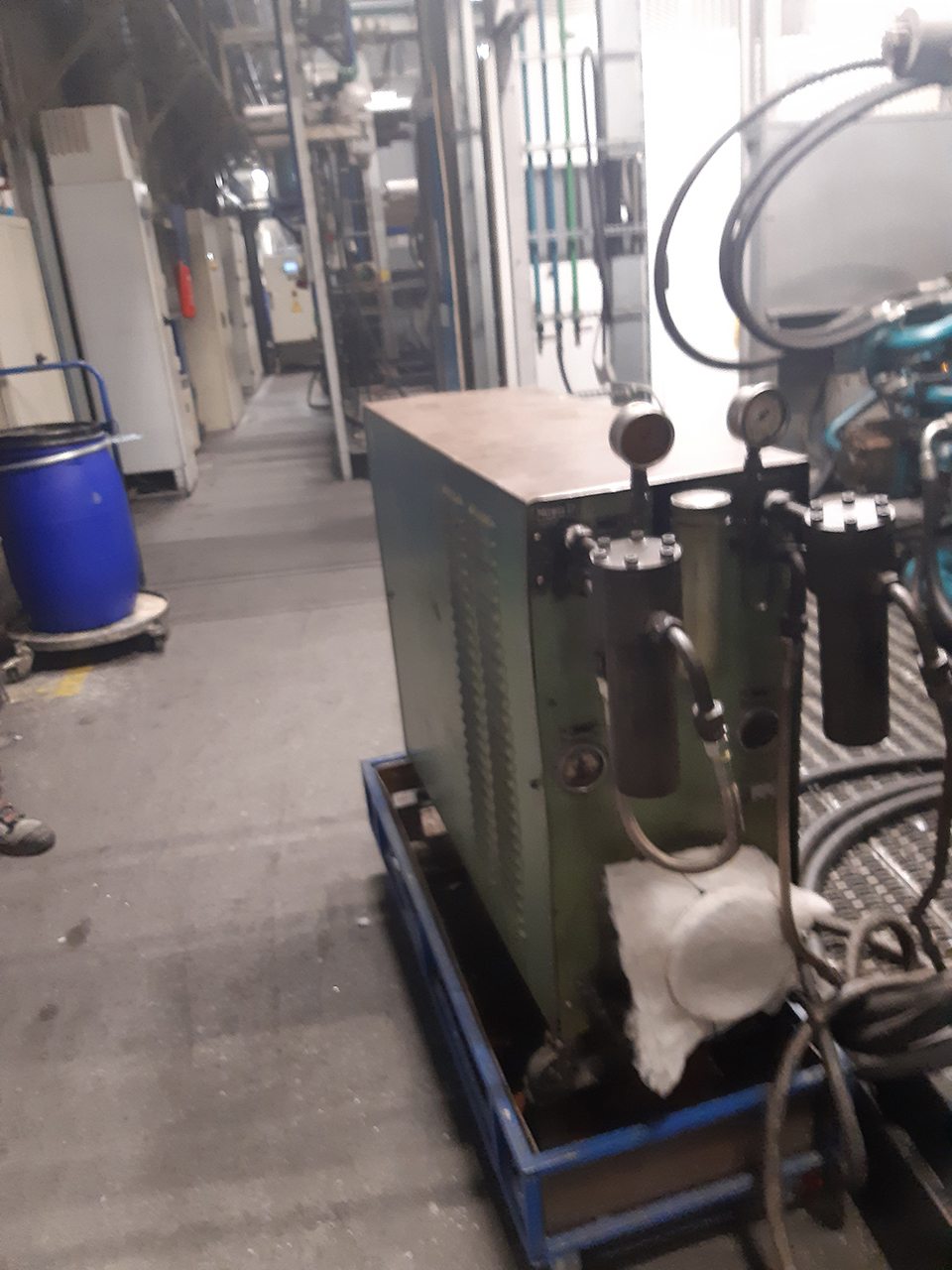

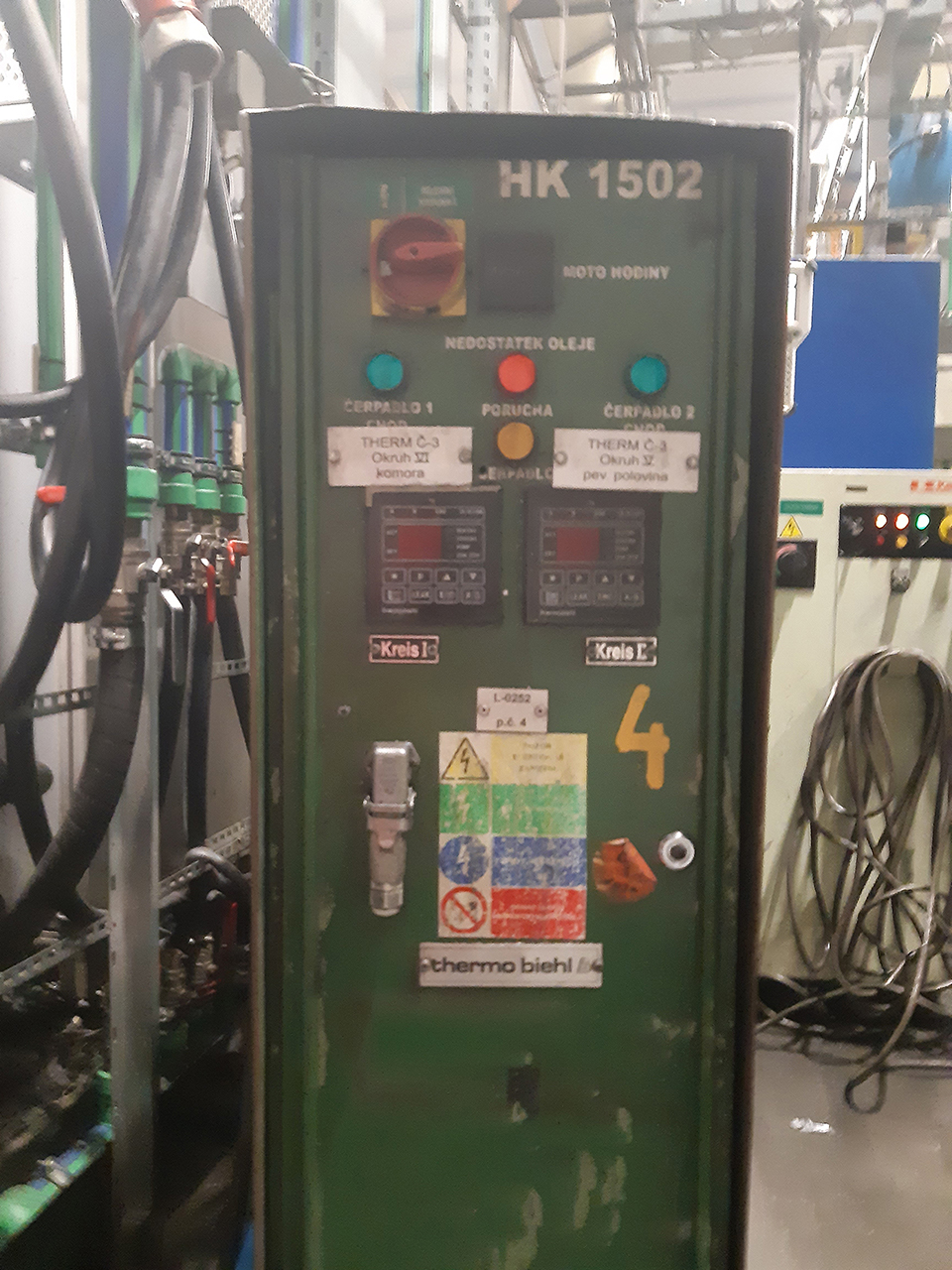

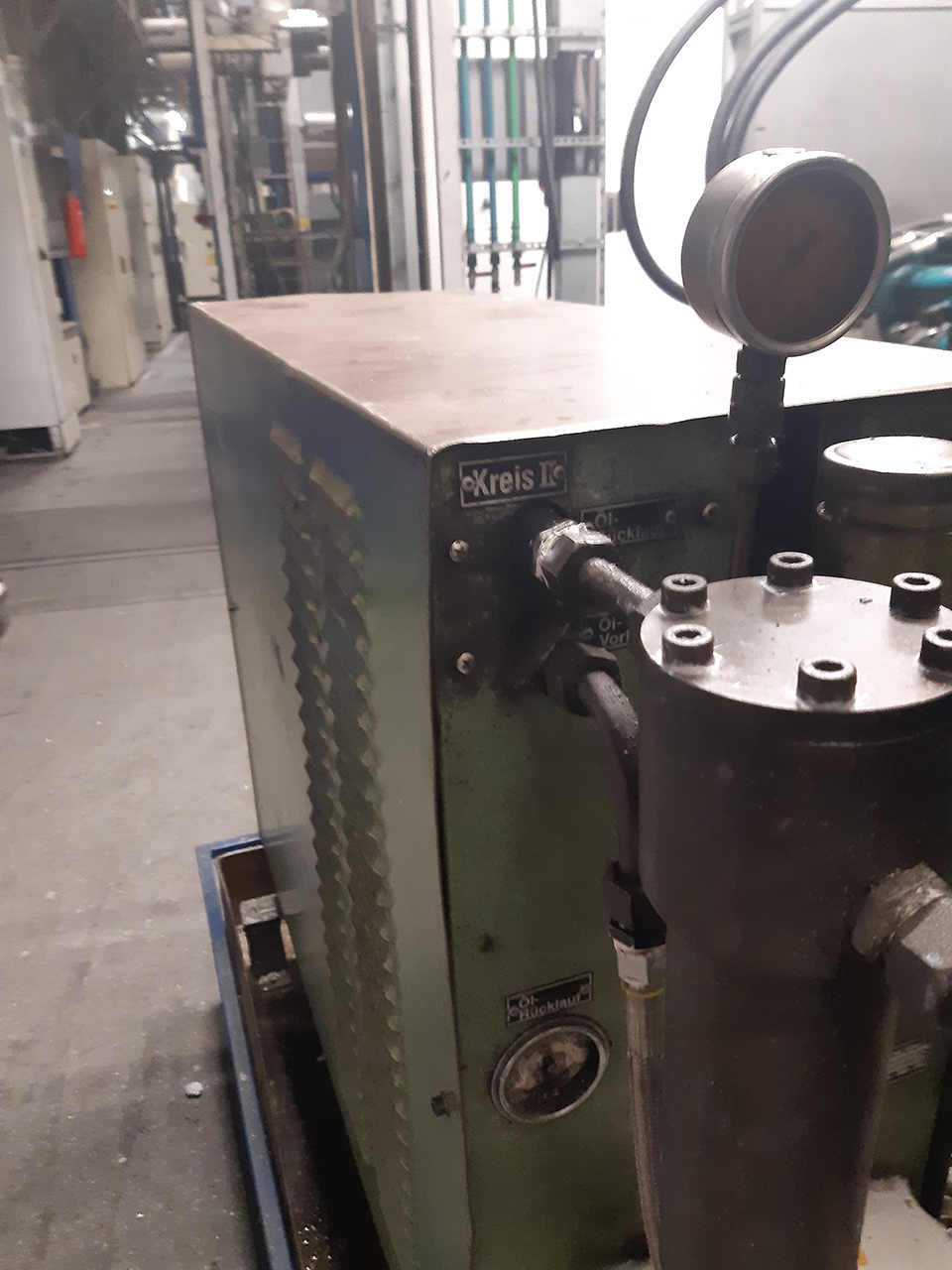

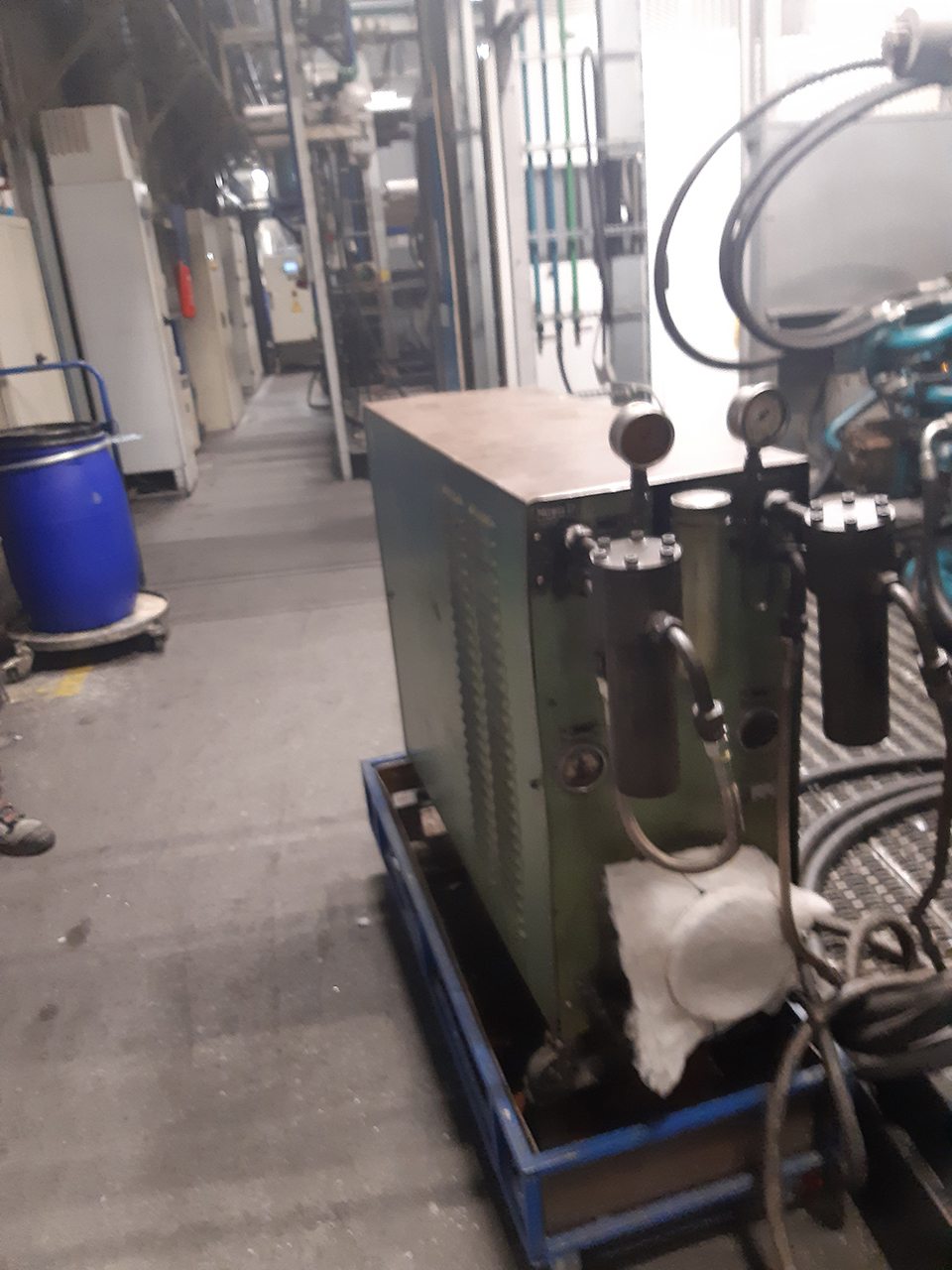

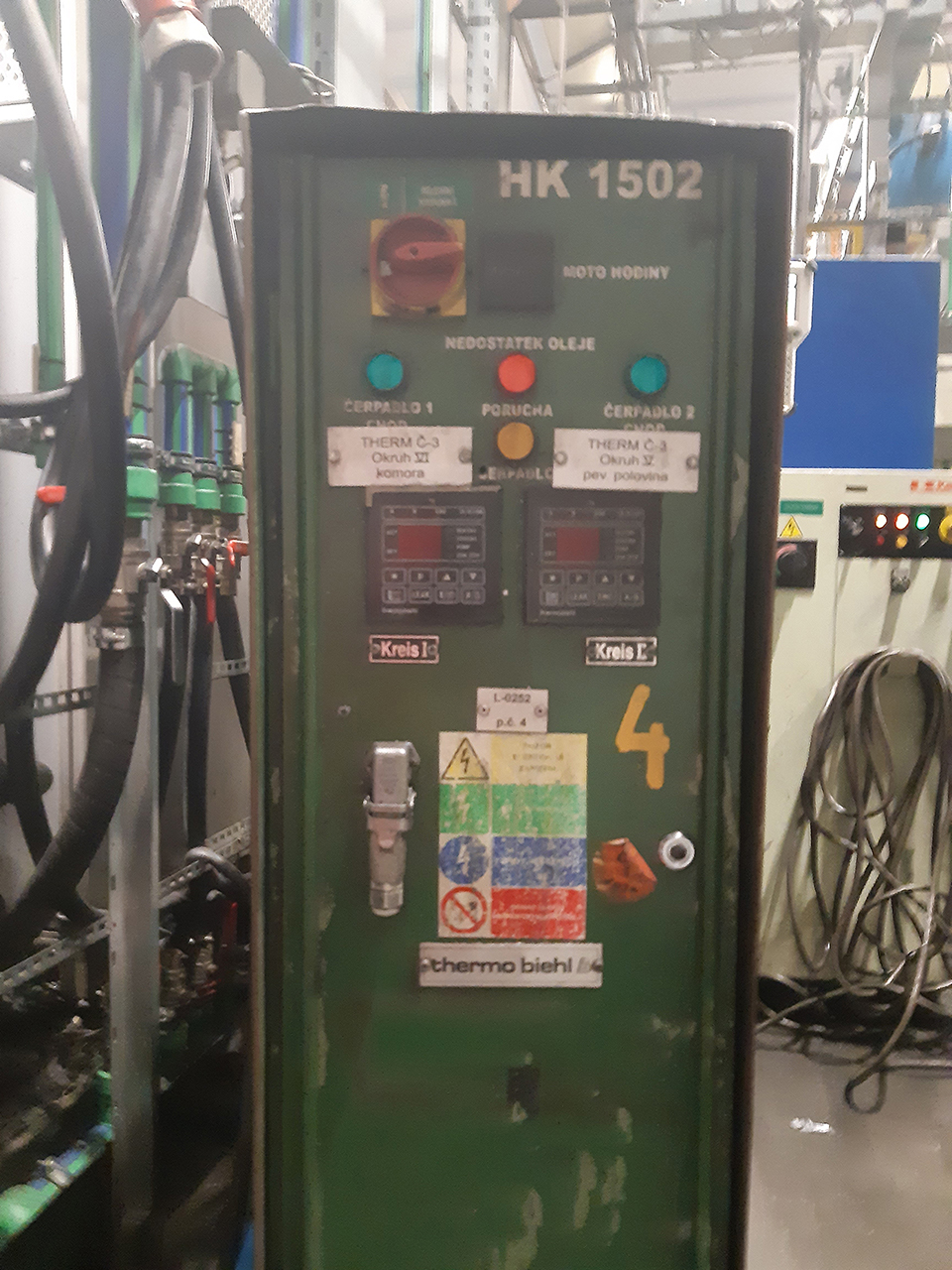

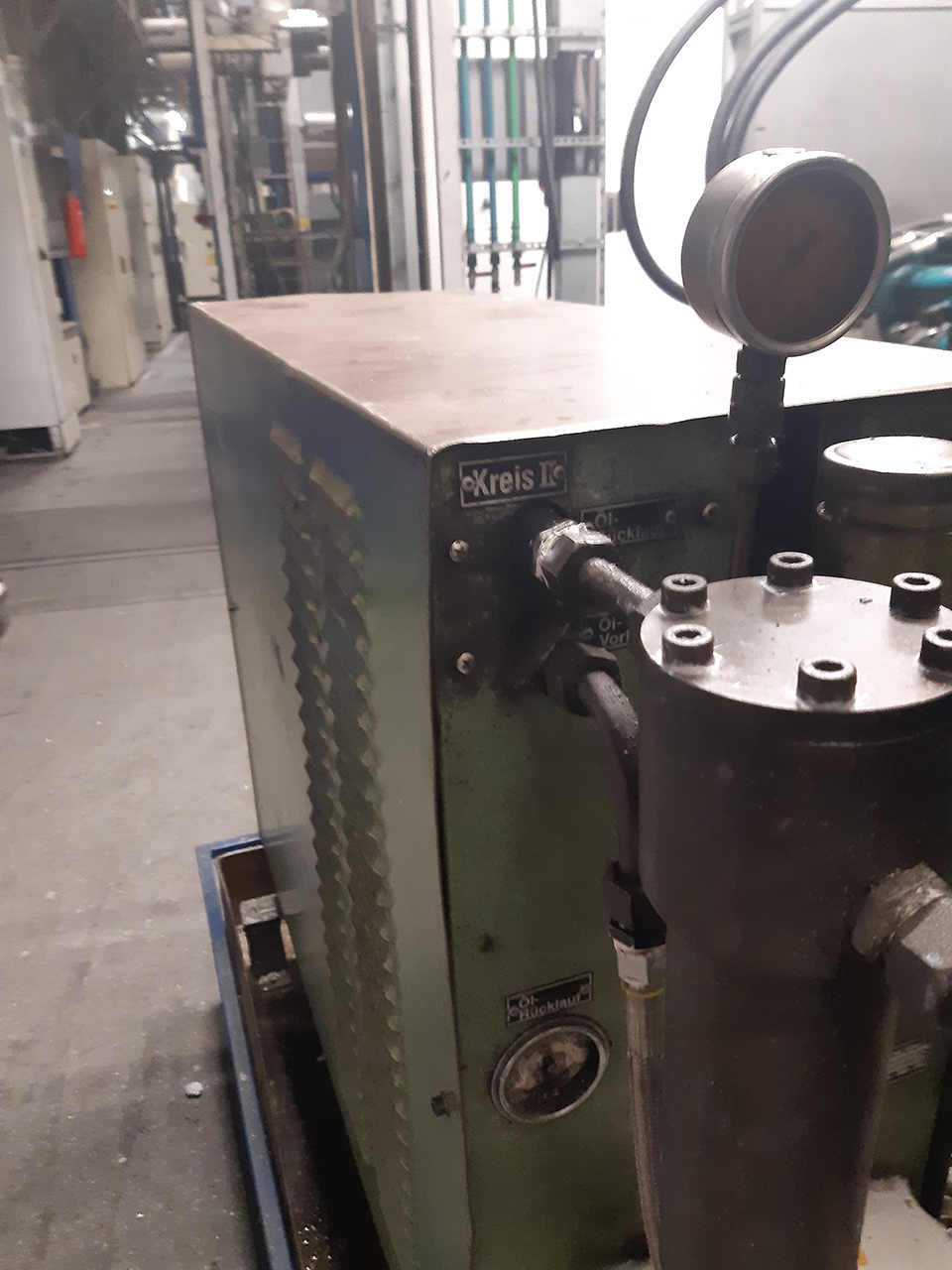

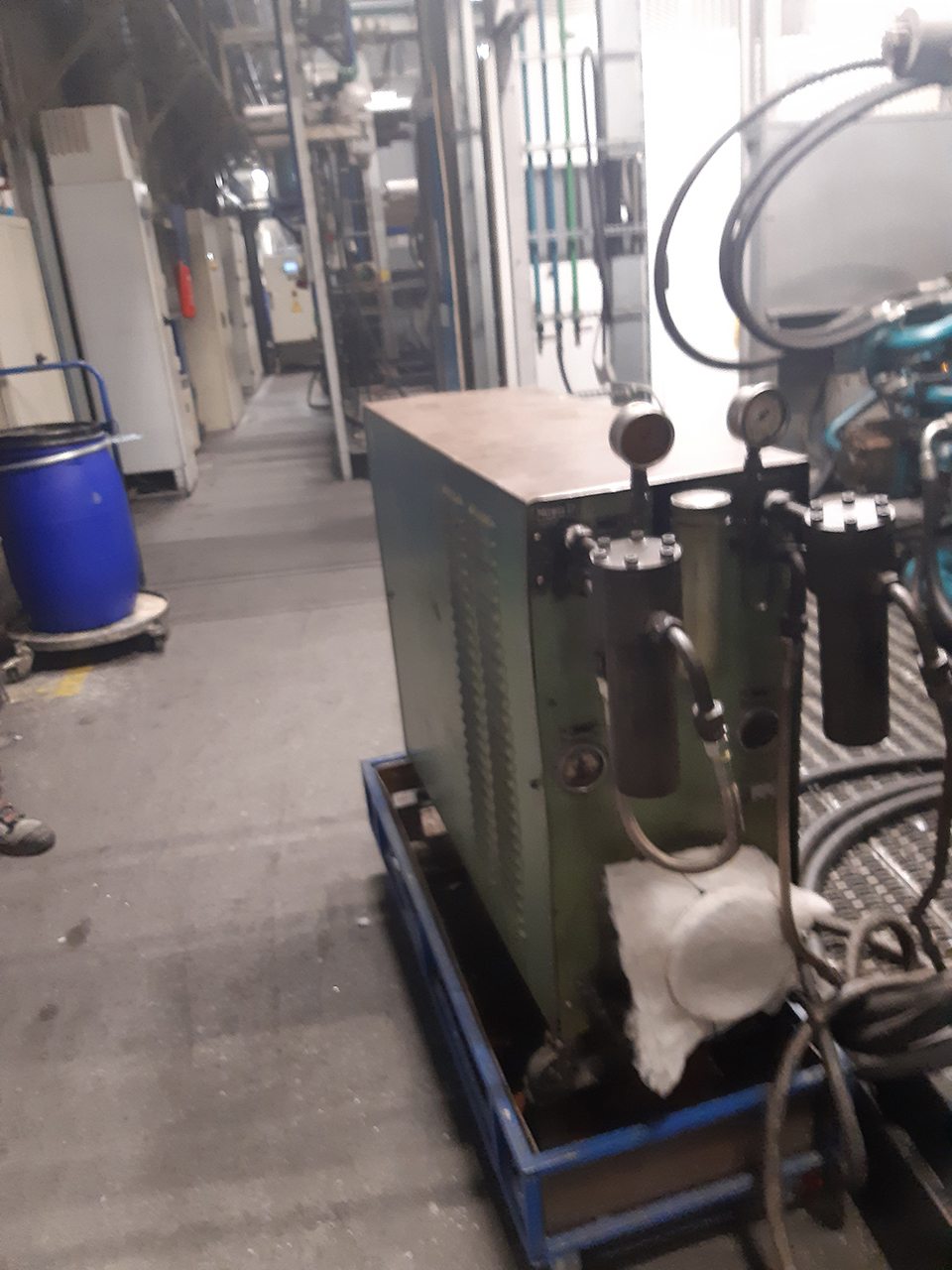

| Temperature control units | available |

| Manufacturer | Thermobiehl |

| Model | L-0252, L-0252, L-0417, L-0417, L0 252 |

| Year | 2007 |

| Comments | with sliding tabel |

| Delivery time | immediately |

| Price | on request |

| Force in [tons]: | 630 |

|---|---|

| Reconditioning: | Coldchamber |

| seo_sold_out: | hide |

Accessory Items

SDM 4000 RS-4 Tie Bar Measuring System Wireless

€1.00*

Tie Bar Measuring System

Model

SDM 4000 RS-4

Scale of delivery

4 RS-measuring amplifier for battery mode

BTRS1

1 battery charger for RS-measuring amplifier

1 charging cable 4-fold

1 Netbook incl. charger

1 measuring-software

1 USB Memory Stick 4 GB

1 measuring case

1 manual

PDF-File on memory stick

Description

RS-measuring amplifier BTRS1

The RS measuring amplifier is placed on the machine tie bar and pressed onto the tie bar surface by means of 2 magnets. When the machine is closed, the resulting strain (change in length) of the tie bar is measured by the built-in strain gauge sensor and the strain measurements are sent to the netbook via the integrated radio module of the RS measuring amplifier. The RS amplifier has a built-in lithium battery with large capacity and charging electronics.

Measuring software

The measuring software uses these values to calculate the load on the individual tie bars and the total closing force of the machine. These values are shown on the netbook display and are also stored in a measurement protocol which contains the date, time of measurement, machine number and mould number. The measurement reports are in EXEL format and can be easily further processed. A graphical measurement diagram is also generated, which can also be saved on a USB stick.

Netbook

11,6“ Netbook, LINUX operating system.

Application

Measuring the strain of tie bars and calculating the locking force of die casting machines and injection moulding machines.

Advantages:

Reducing of tie bar breaks

Control of the evenly distributed tie bar strain

Consistend touching of ejector die and cover

Consistend touching of ejector die and cover

Reduction of flash

Optimization of strain in the locking unit

Wireless transfer (Bluetooth)

Compact construction

For all tie bar diameters (from 30mm)

Also for rough tie bar surfaces

High resolution 1 µm

Full scale 0.5 mm

Delivery time

on request

Price

on request