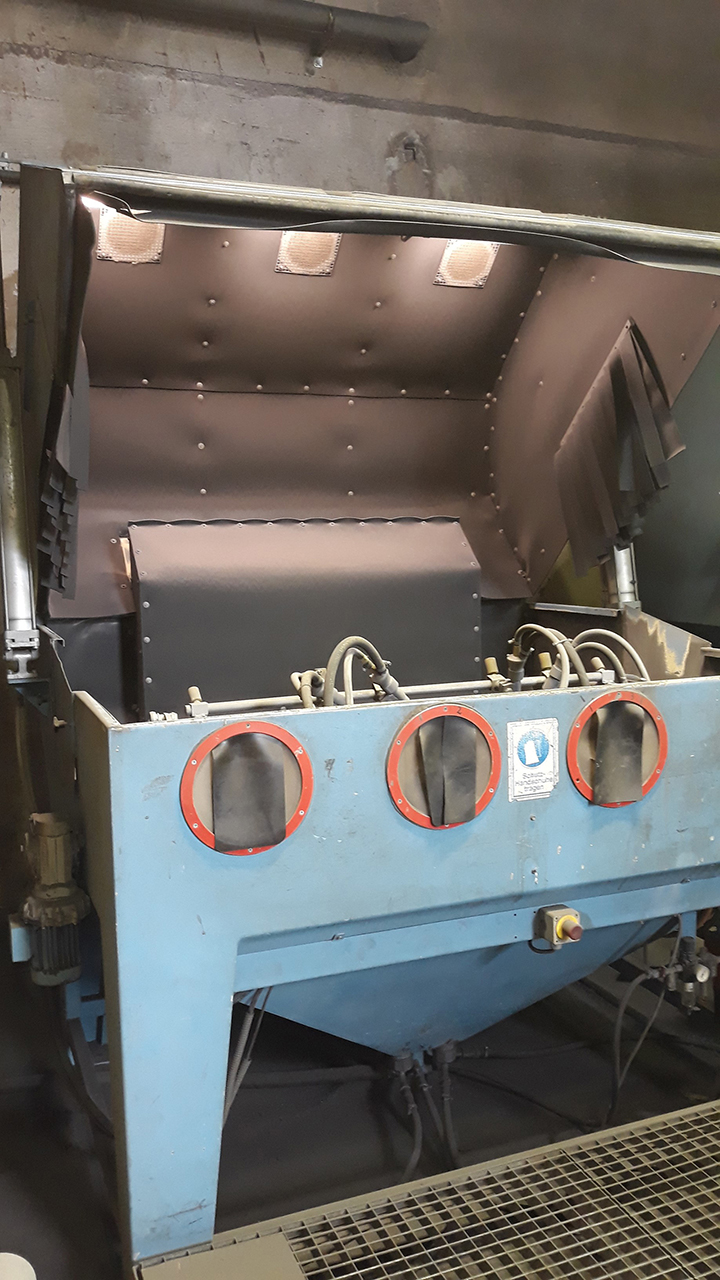

Our used shot blast machines are used for surface treatment, i.e. for deburring, desanding, descaling, derusting and roughening, treating the surfaces of castings and forgings made of steel, aluminium, magnesium, zinc and brass.

Leading manufacturers of shot blast machines include DISA, Schlick, Hunziker, OMSG, Wheelabrator, Carlo Banfi, Turbotecnica, V&S, MHG, Auer, Lortz, OTI, Rump, Agtos, GF Georg Fischer, BMD, Gutmann, Gietart, Tilghman, Vogel und Schemann, Berger, Rösler, Walther Trowal and others.

If the blast machine is combined with appropriate cross-conveyor systems, individual production sections can be efficiently interlinked. This results in a flexible production process and with a high material output.

Why are used blasting machines so popular and versatile?

Why are used blasting machines so popular and versatile? The quality of technical products and materials can be recognised, among other things, by the functionality and aesthetics of their surfaces. In most cases, a particularly well finished surface also contributes to better market success. That is why high-quality surface finishing is all the more important today. Depending on the model, used blasting machines from fiss machines offer the possibilities of deburring, descaling, desanding and derusting, roughening, matting, smoothing and edge rounding, right up to hardening.

Blasting technology is a technical process that enables a wide variety of applications, especially for metallic surfaces.

Depending on the mode of operation, type of transport and requirements for the workpieces, new and used blasting machines are divided into different types:

- Continuous blast machine

- Roller conveyor shot blast machine

- Overhead conveyor shot blast machine

- Turntable shot blast machine

- Trough belt shot blast machine

- Blast wheel shot blast machine

- Sand blasting machines

- Wire belt shot blast machine

- Diabolo shot blast machine

- Walking beam shot blast machine

- Caterpillar belt shot blast machine

- Belt shot blast machine

- Continuous overhead conveyor blast machine

These materials are processed in blasting machines:

A wide variety of workpieces, castings and forgings made of steel, aluminium, magnesium, zinc and brass can be processed in blasting machines using the appropriate blasting media. The processing of mineral building materials such as concrete, sandstone, glass, textiles and wood as well as plastics is also easily possible with these machines.

How to find the right abrasive for your used blasting machine:

Blasting media are available in a wide variety of materials for a wide variety of applications and materials. It is best to consult a blasting media specialist to find out which blasting media is best suited for your purpose. It is best to answer the following questions in advance.

- Type of surface to be blasted, if necessary also the material of the substrate.

- Dimension and shape of the surface, reason for blasting

- Type of blasting equipment/blasting machine

- Surface condition before treatment

- Desired surface condition after treatment

- Is only the surface to be polished or does the process go deeper?

- If a coat of paint is applied after the blasting process, what surface roughness must be achieved?

Used shot blast machines including real expert knowledge from fiss machines

The used shot blast machines are offered in the condition "as it is". Depending on the condition and your budget, you will receive a proposal from us for an recondition or modernisation.

No suitable blast machine in the range? Always ask us, thanks to our contacts we can help you quickly or offer you brand new blasting machines with the blasting media, spare parts and accessories.