Reconditioning of hot chamber die casting machine

Product information "Reconditioning of hot chamber die casting machine"

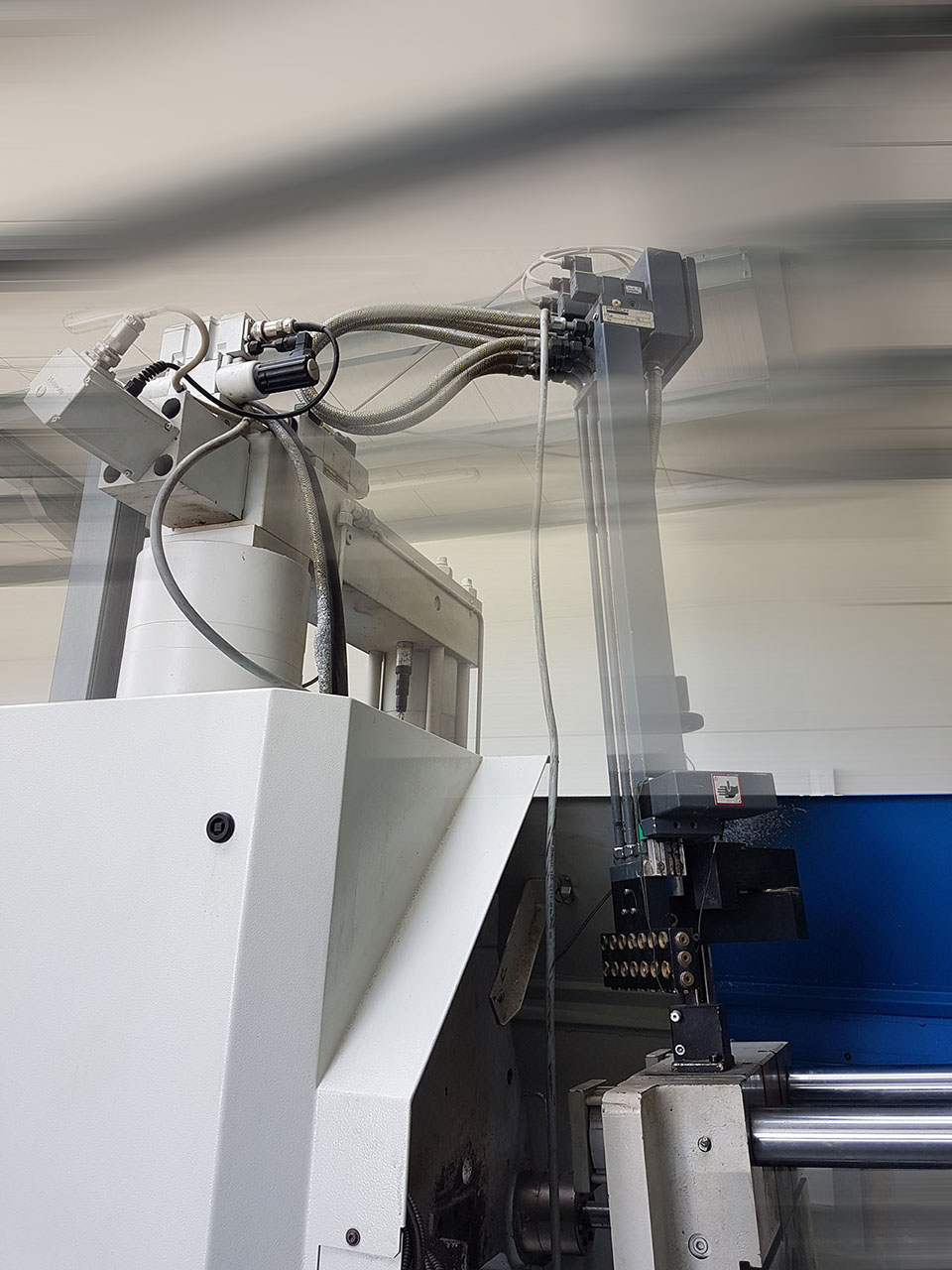

Reconditioning of hot chamber die casting machine

| Scope of performance | functional control |

Closing unit overhaul |

Part overhaul |

General overhaul |

| Cleaning, disassembly and measurement | x | x | x | x |

| Inspection for cracks | x | x | x | x |

| Face milling of clamping plates | optional | x | x | x |

| Rework ejector holes and T-slots | optional | x | optional | x |

| Exchange of all bushings and bolts | optional | x | optional | x |

| Reworking the toggle system | optional | x | optional | x |

| Revision of injection cylinder, hydraulic ejector and closing cylinder, |

optional | x | optional | x |

| Hydraulic overhaul | optional | x | optional | x |

| Mechanical overhaul | optional | x | optional | x |

| Overhaul of control system | optional | -- | optional | -- |

| Renewal of control system | -- | -- | -- | x |

| Integration Druckgussparameter-Messung | optional | -- | optional | x |

| Integration of die casting parameter measurement | optional | optional | optional | optional |

| Retrofitting clamping force measurement | optional | optional | optional | optional |

| Retrofitting die internal pressure measurement | optional | -- | optional | x |

| Overhaul melting and holding furnace | optional | -- | optional | x |

| Overhaul of spraying system | optional | -- | optional | x |

| Overhaul of weight sensing device | optional | -- | optional | x |

| Overhaul of conveyor belt | optional | -- | optional | x |

| Closing unit measurement with protocol | x | x | x | x |

| Acceptance in dry cycle | x | -- | x | x |

x = included, -- not available

Delivery times: The delivery time depends on the scope of services and the machine size. In the case of closing unit overhauls, we offer interchangeable closing units depending on the make and size of the machine.

Warranty: 12 months on new parts.

Recommissioning, process optimisation, training by experienced engineers and technicians.