Reconditioning of low pressure die casting machine

Product information "Reconditioning of low pressure die casting machine"

| Construction – machine frame |

| - Repair oft he machine frame |

| - Bearing replacement |

| - Sandblasting and pinting |

| Hydraulik |

| - Modernisaton of the hydraulic equipement (improved reliability and longer lifespan of components) |

| - Repair and replacement of the hydraulic units (pump, pump control, filtering in the return line and secondary circuit, temperature and fluid level control) |

| - Cylinder repair (seals, piston rod, cylinder tube) |

| - Replacement or repair of the steel installation |

| - Replacement of hoses |

| - Installation of the temperature protection on the exposed hoses |

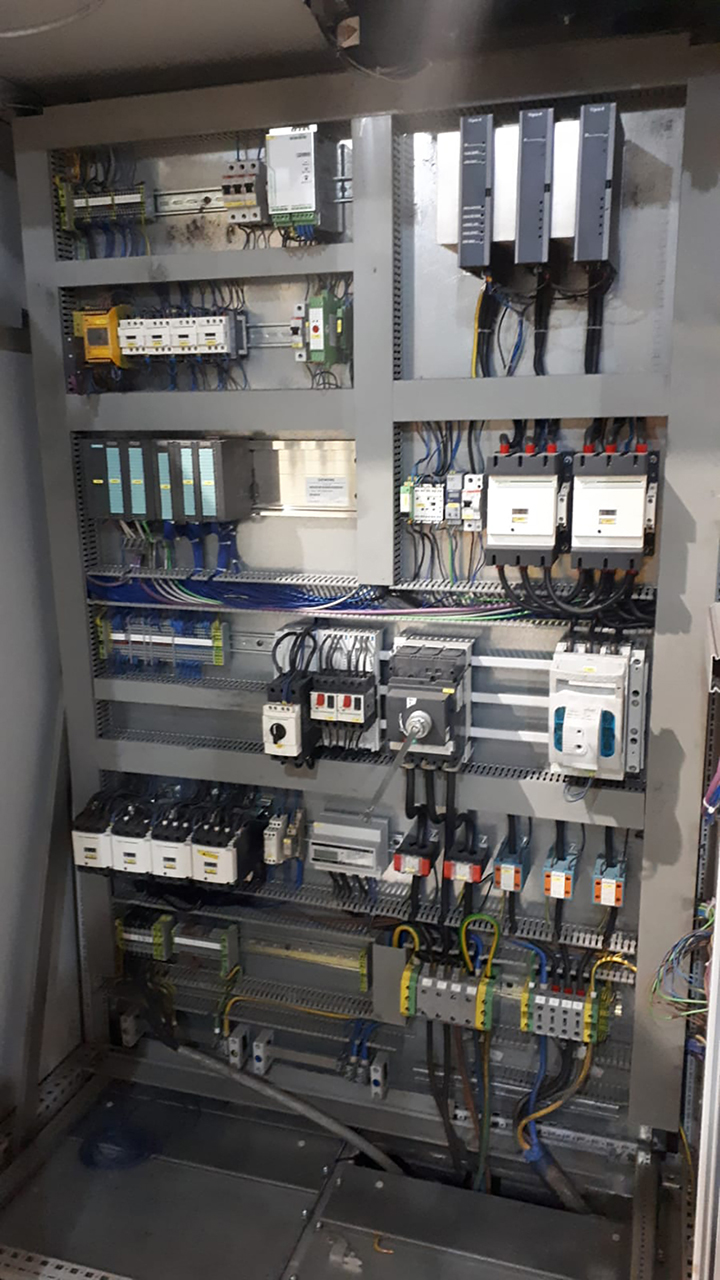

| Electrical equipment and control |

| Electrical equipment: |

|

- Electric cabinet - PLC SIEMENS S7 - Electro installation on the machine - Sensors, PLC card for the temperature probes |

| Software: |

|

- Automation of the machine – easy programming and storing of the casting programmes - Setting of casting parameters for the machine operating (melt temperature, mold temperature) |

| Gas Equipment |

| - Renovation of the gas equipment for mould heating |

| - Renovation of the existing installation from the connection from the gas network to the burners on the machine |

| Colling cabinets |

| - Production of the cooling circuits for moulds cooling with air |

| - Regulation of the flows of the cooling air |

| Casting machine protection fence |

| - Manufacturing of the casting machine protecting fence according to existing guidelines |

| - When casting with robots there will be automatic doors installed |

| Modernization of the hydraulic aggregate – extended lifespan |

| - Pump - change of the position if needed |

| - Manufacturing of the secondary filter circuit |

| Delivery time | on request |

| Price | on request |