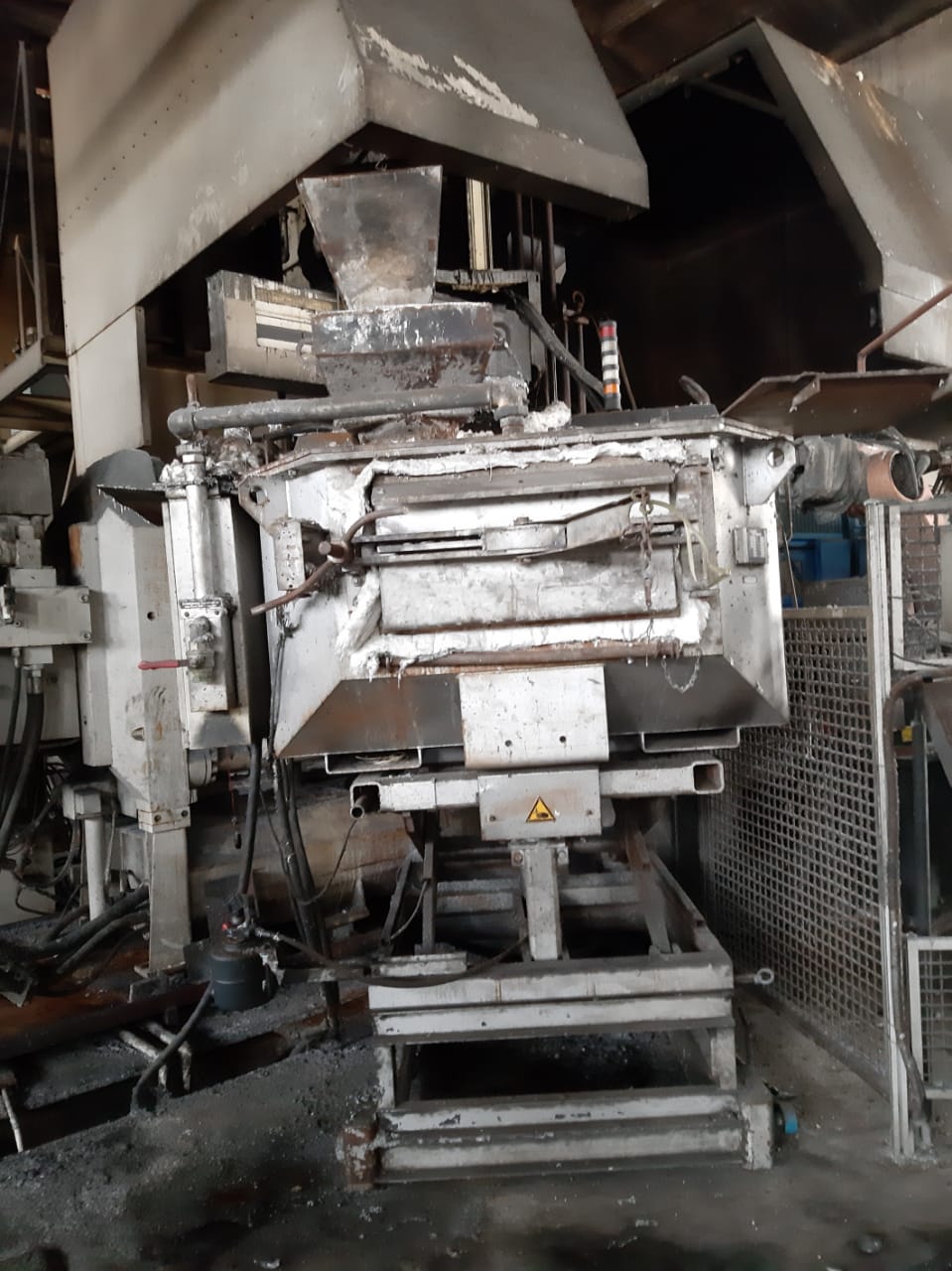

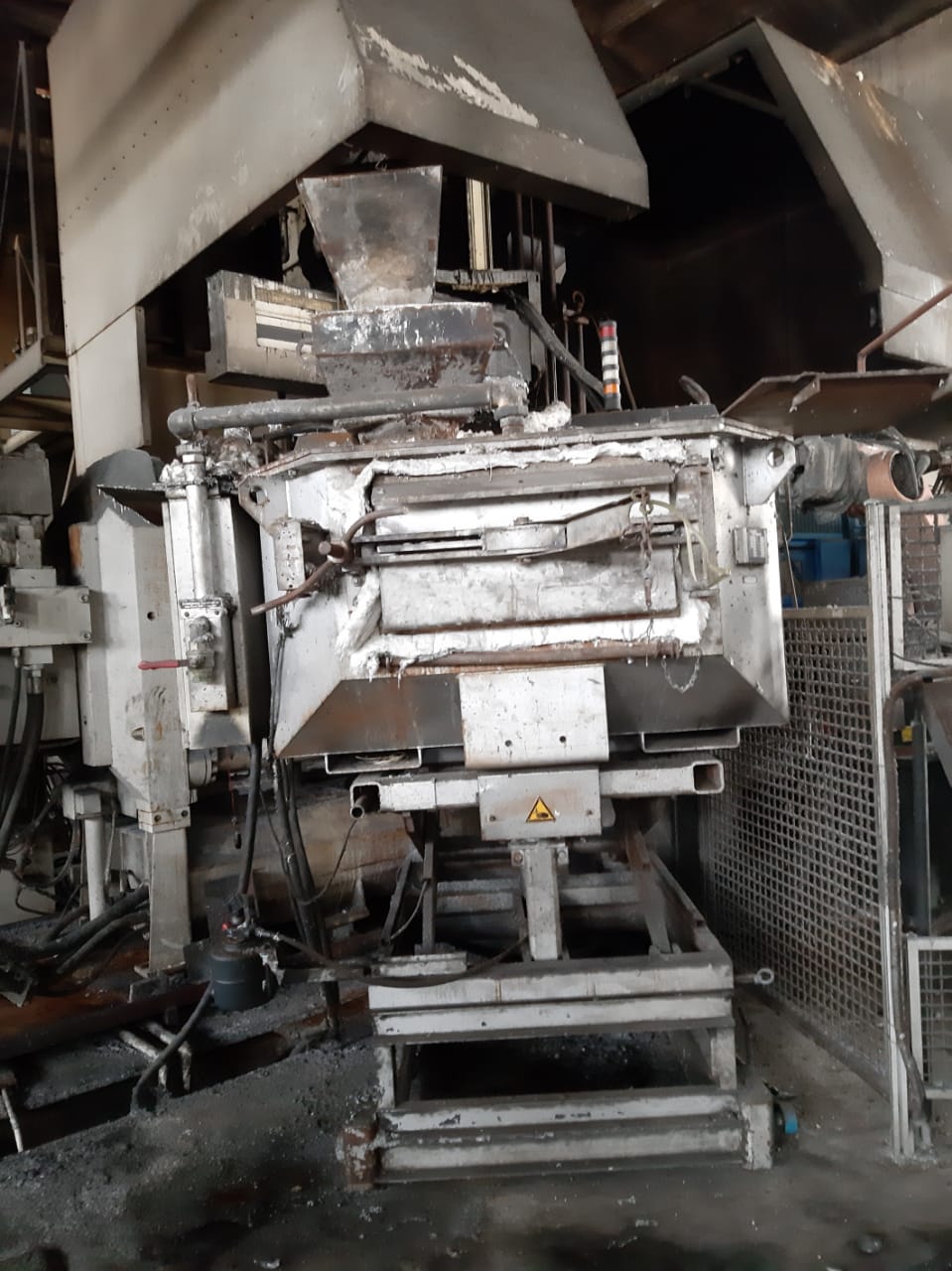

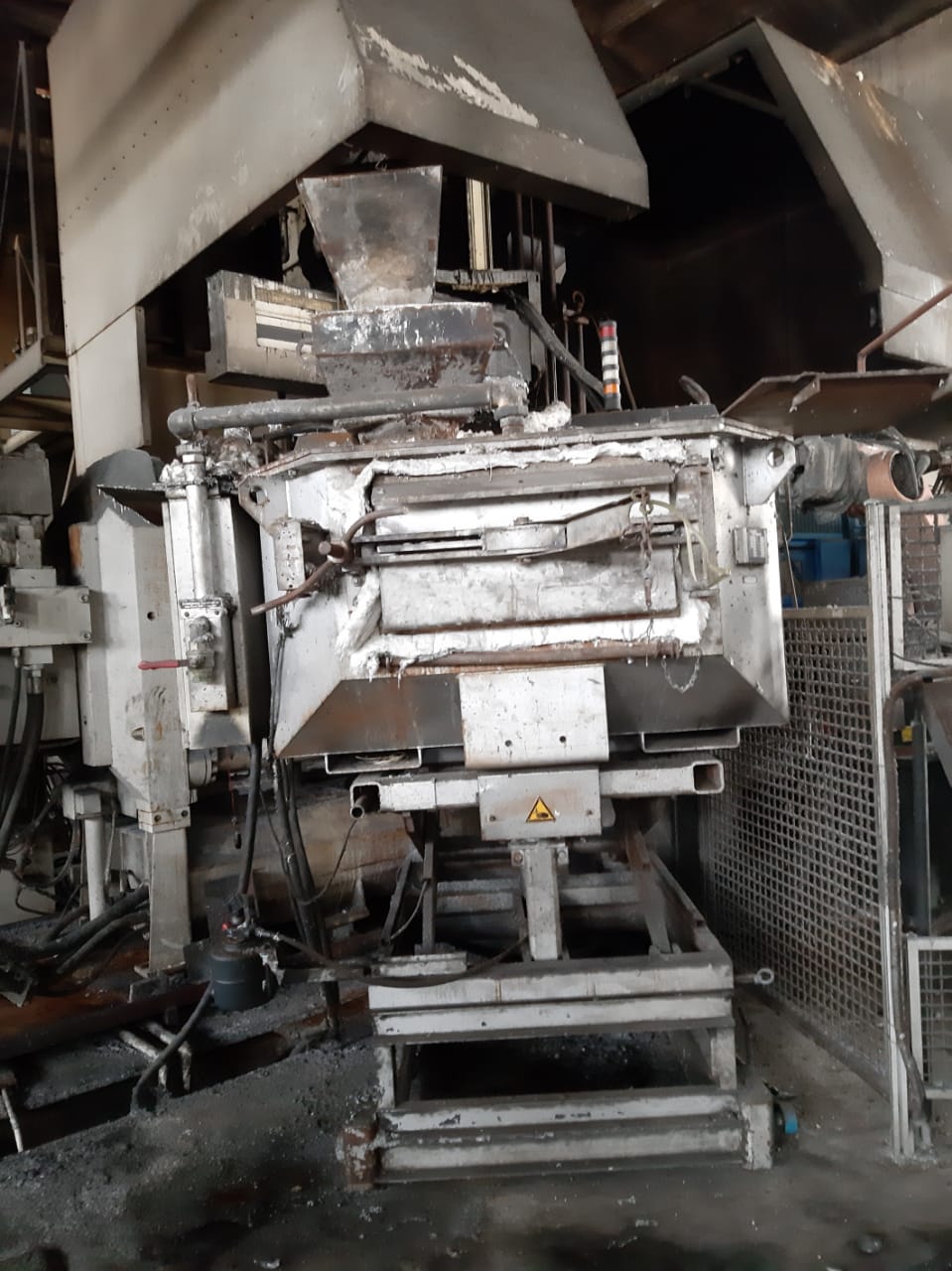

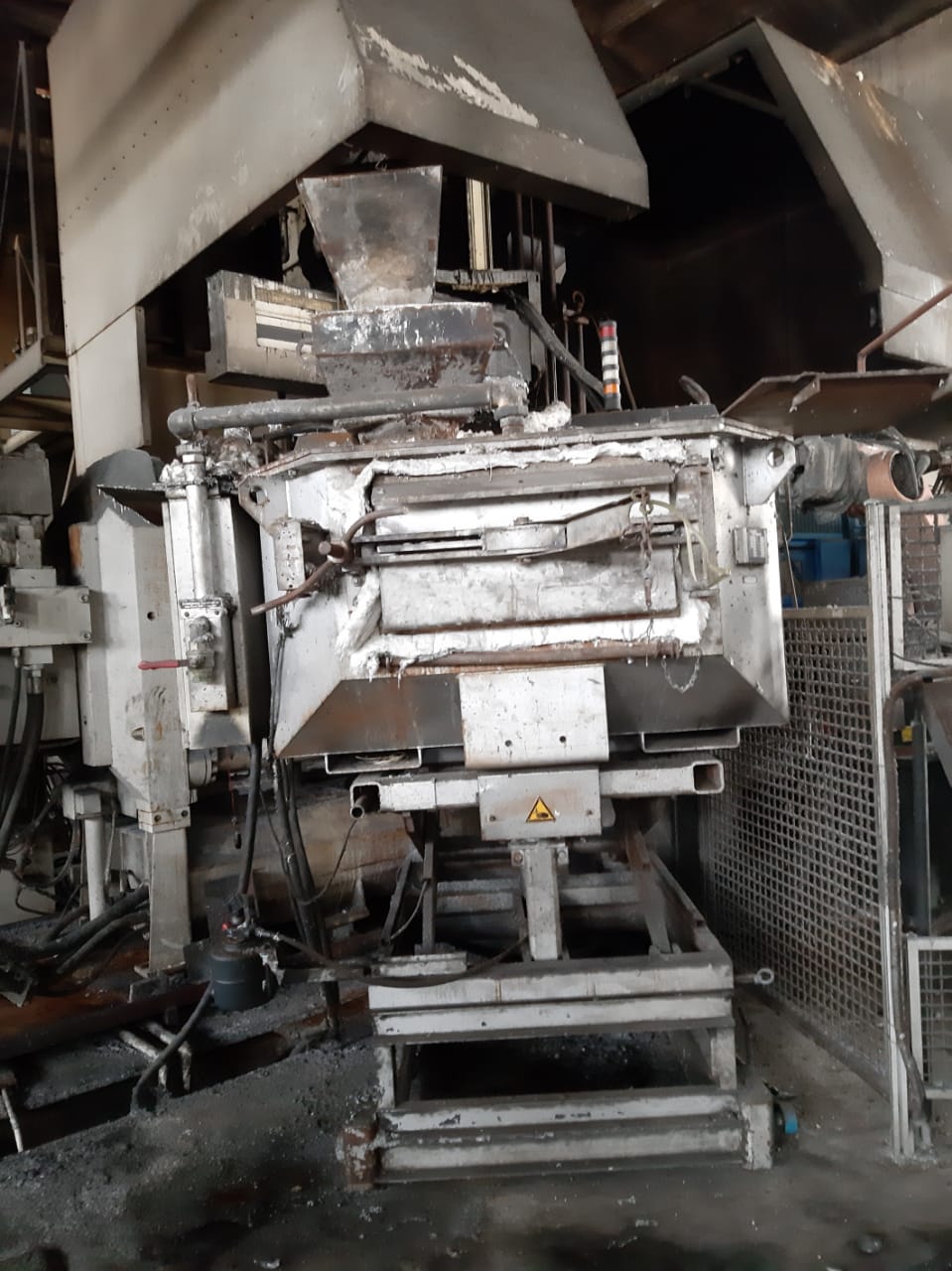

Frech DAK 1100-112 Soğuk kamaralı basınçlı döküm makinesi KK1548

Product information "Frech DAK 1100-112 Soğuk kamaralı basınçlı döküm makinesi KK1548"

| Máquina de fundição sob pressão | |

| Fabricante | Frech |

| Modelo | DAK 1100-112 |

| Força de Bloqueio | 12100 kN |

| Sistema de controle | Diálogo de Dados 2 |

| Ano de fabrico | 2010 |

| Comentários | para fundição sob pressão de alumínio |

Acessórios

| Fornalha | disponível |

| Fabricante | StrikoWestofen |

| Modelo | W 1200 |

| Capacidade | 1200 kg |

| Ano | 2010 |

| Sistema de controle | ProDos |

| Aquecimento | elétrico |

| Comentários |

| Máquina de Pulverização | disponível |

| Fabricante | Frech |

| Modelo | Spraymotion 2 |

| Ano | 2010 |

| Comentários |

| Unidade extrator | disponível |

| Fabricante | Kuka |

| Modelo | KR 60 |

| Sistema de controle | |

| Ano | 2010 |

| Exaustão | disponível |

| Fabricante | Keller |

| Modelo | |

| Ano | 2010 |

| Unidade de controlo de temperatura | disponível |

| Fabricante | Robamat |

| Modelo | 5212 |

| Ano | 2010 |

| Comentários |

| Prazo de entrega | imediatamente |

| Preço | mediante solicitação |

| Reconditioning: | Coldchamber |

|---|---|

| [ton] cinsinden kuvvet: | 1100 |

| seo_sold_out: | hide |

| Üretim yılı: | 2010 |

Aksesuar Ürünleri

SDM 4000 RS-4 Bağlantı Çubuğu Ölçüm Sistemi Kablosuz

€1,00*

Bağlantı Çubuğu Ölçüm Sistemi

Model

SDM 4000 RS-4

Teslimat ölçeği

4 Akü modu için RS-ölçüm amplifikatörü

BTRS1

1 RS-ölçüm amplifikatörü için akü şarj cihazı

1 şarj kablosu 4 katlı

1 Netbook, şarj cihazı dahil

1 ölçüm-yazılımı

1 USB Bellek Çubuğu 4 GB

1 ölçüm çantası

1 el kitabı

Bellek çubuğunda PDF-Dosyası

Açıklama

RS-ölçüm amplifikatörü BTRS1

RS ölçüm amplifikatörü makine bağlantı çubuğunun üzerine yerleştirilir ve 2 mıknatıs aracılığıyla bağlantı çubuğu yüzeyine bastırılır. Makine kapatıldığında, bağlantı çubuğunun ortaya çıkan gerinimi (uzunluktaki değişim) dahili gerinim ölçer sensör tarafından ölçülür ve gerinim ölçümleri RS ölçüm amplifikatörünün entegre radyo modülü aracılığıyla netbook'a gönderilir. RS amplifikatörü, büyük kapasiteli ve şarj elektroniğine sahip dahili bir lityum pile sahiptir.

Ölçüm yazılımı

Ölçüm yazılımı bu değerleri kullanarak her bir bağlantı çubuğu üzerindeki yükü ve makinenin toplam kapatma kuvvetini hesaplar. Bu değerler netbook ekranında gösterilir ve ayrıca tarih, ölçüm saati, makine numarası ve kalıp numarasını içeren bir ölçüm protokolünde saklanır. Ölçüm raporları EXEL formatındadır ve kolayca işlenebilir. Ayrıca bir USB belleğe kaydedilebilen grafiksel bir ölçüm diyagramı da oluşturulur.

Netbook

11,6" Netbook, LINUX işletim sistemi.

Uygulama

Bağlantı çubuklarının gerilmesinin ölçülmesi ve kalıp döküm makinelerinin ve enjeksiyon kalıplama makinelerinin kilitleme kuvvetinin hesaplanması.

Avantajlar:

Bağlantı çubuğu kırılmalarının azaltılması

Eşit dağılımlı bağlantı çubuğu gerilmesinin kontrolü

Ejektör kalıbına ve kapağına sürekli dokunma

Ejektör kalıbına ve kapağına sürekli dokunma

Flaşın azaltılması

Kilitleme ünitesindeki gerilmenin optimizasyonu

Kablosuz aktarım (Bluetooth)

Kompakt yapı

Tüm bağlantı çubuğu çapları için (30 mm'den itibaren)

Pürüzlü bağlantı çubuğu yüzeyleri için de

Yüksek çözünürlük 1 µm

Tam ölçek 0,5 mm

Teslimat süresi

istek üzerine

Fiyat

istek üzerine