We offer used horizontal CNC machining centres and vertical CNC machining centres, vertical machining centres, CNC milling machines, CNC transfer machines and CNC lathes from well-known manufacturers such as MAZAK, Mori Seiki, OKUMA, OKAMOTO, DMG (Deckel, Maho, Gildemeister), Chiron, Stama, Heller, INDEX, Traub, EMCO, Steinel, Brother, EMAG, SW Schwäbische Werkzeugmaschinen, Gnutti, Bridgeport, GOZIO, Haas, Picchi, Ledwell, Bugatti, YCM, Riello, HYUNDAI, DAEWOO.

Whether new or used: The machining centres we offer are used for the machining of components made of steel, die castings, gravity die castings and low-pressure castings made of aluminium, magnesium and zinc.

Compared to conventional universal machines and CNC machines, machining centres are characterised by their significantly higher productivity.

What are the benefits of machining centres for the metal-cutting industry and which machining centres are available?

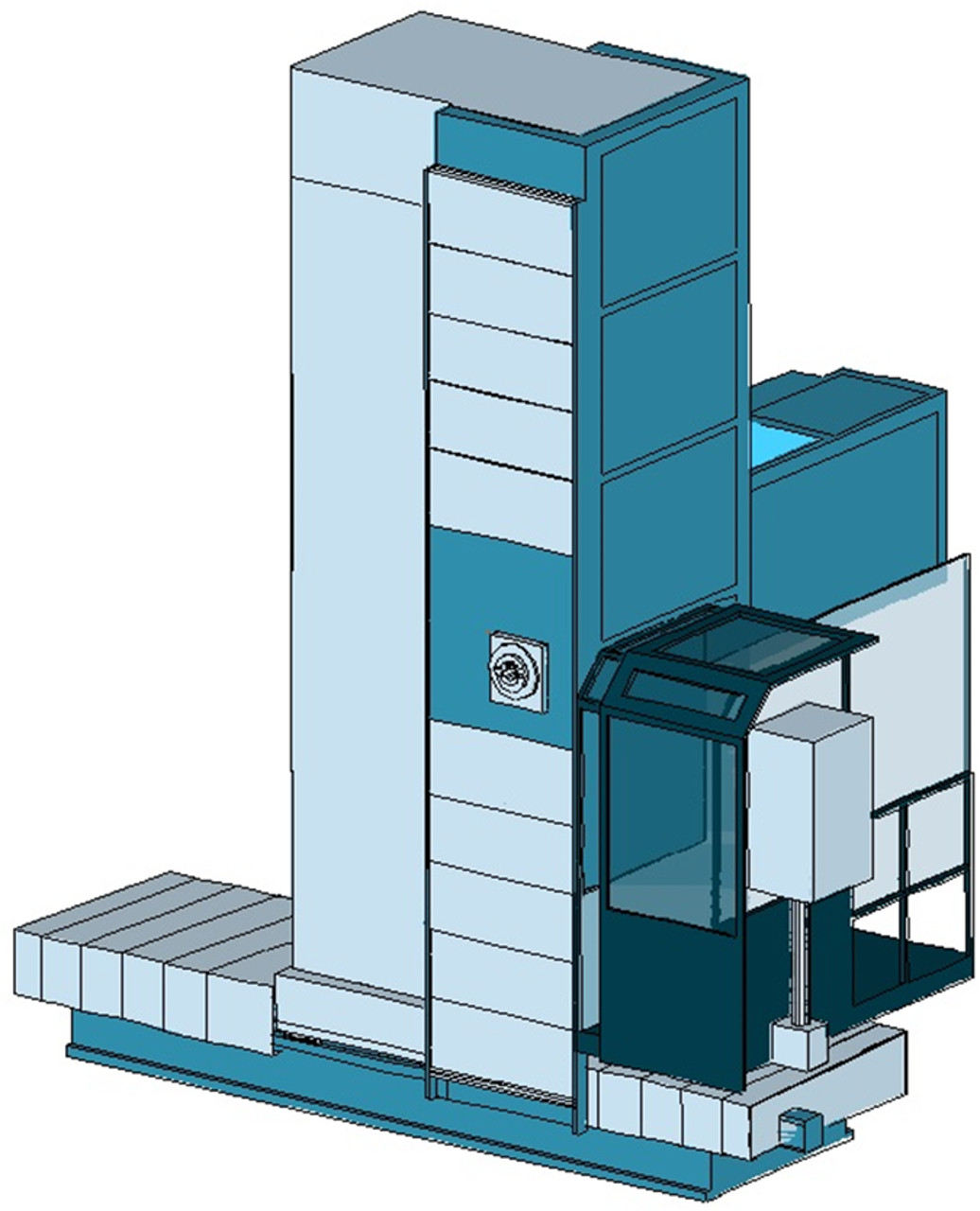

Whether it is a machining centre or a machining centre (BAZ), this is a machine tool that is perfectly suited for the complete machining of metal components. The functions of a lathe, milling machine and drilling machine are contained in a single machine. It is also possible to change tools automatically. We differentiate machining centres into horizontal BAZ and vertical BAZ according to the construction direction of the main spindle.

There are also other designations for machining centres, depending on their respective basis:

- A flexible manufacturing cell is a machining centre with additional automatic workpiece change.

- A turning centre is a machining centre with the design basis of a lathe.

- If the machining centre has a workpiece changer, it is called a turning cell.

- Without certain extras, machining centres are often designed on the basis of a milling machine.

Used machining centres are highly efficient multitaskers:

Whereas in the past there were machining centres with only one main spindle, today machining centres with up to five spindles can be found in the metalworking industry. The latter are used for complex geometries that are particularly difficult to machine.

The advantages of multi-spindle machining are:

- Higher output with the same footprint

- Lower personnel costs, as only one machine is installed and operated

- Lower life-cycle costs

- Particularly high productivity

These materials are machined in used machining centres:

A wide variety of metallic materials are processed in used machining centres for the casting industry. These include: Steel, die castings, gravity die castings as well as low pressure castings made of aluminium, magnesium and zinc.

Used CNC processing machines including real expert knowledge from fiss machines

The used processing machines are offered in "as is" condition. In accordance with this and your budget, we will be pleased to work out an individual proposal for an overhaul or modernisation for you.

No suitable processing machine available? Always ask us, thanks to our contacts we can help you quickly or offer you brand new machines.