- Used Machines

- News

- Search Machines

- Your Offer

- Accessories

- Service

- Events

- About us

- Contact

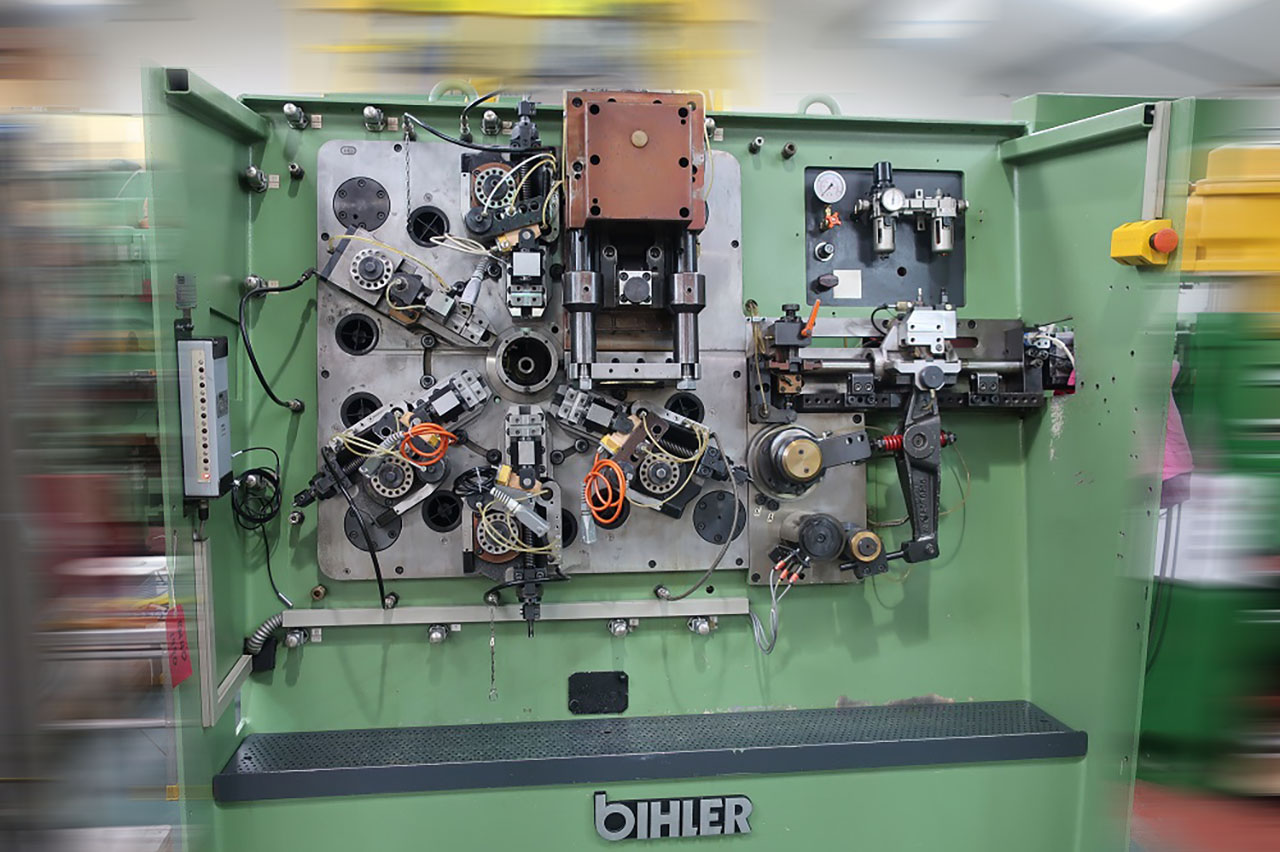

For the cold forming of metal you will find used mechanical and hydraulic presses from various years of construction and from many leading manufacturers such as: Aida, Alba, Andritz Kaiser, Arisa, Arku, Atkins, Benelli, Beutler, Bihler, Bliss, BMU, Bruderer, Clearing, Colombo, Dangelmeier, Danly, Dieffenbacher, Dunkes, EBU, Edelhoff, Eitel, Erfurt, Erfurt Krupp, EUMUCO, Exner, FAGOR, Gebr. Röcher, Gräbener, GSW, Hatebur, Hans Schön, Haulick + Roos, Heilbronn, Helmdering, Heuser, HYDRAP, Hydromec, Innocenti, IWK, Kaiser, Kindsmüller, Krupp, Lasco, Lauffer, Leinhaas, Linde, MABU, Manzoni, May, Mecfond, Mecolpress, Müller, National, Neff, Oevermann, Oxford, Pelessier, Pelz, PSE, Raster, Raskin, Reis, Rheinmetall, Richter, Rovetta, Ruhrmann, Schuler, Seuthe, Siempelkamp, Smeral, SMG, Soenen, Thölen, USI, Wagner, Raster Zeulenroda, Zani.

Used presses for metal processing

Our used presses can be divided into mechanical and hydraulic presses. They differ in power and working speed. Hydraulic presses are the "powerhouses" with strong pressing force but slow stroke. Series production is therefore dominated by mechanical presses with short cycle times, e.g. eccentric presses, spindle presses and toggle presses.

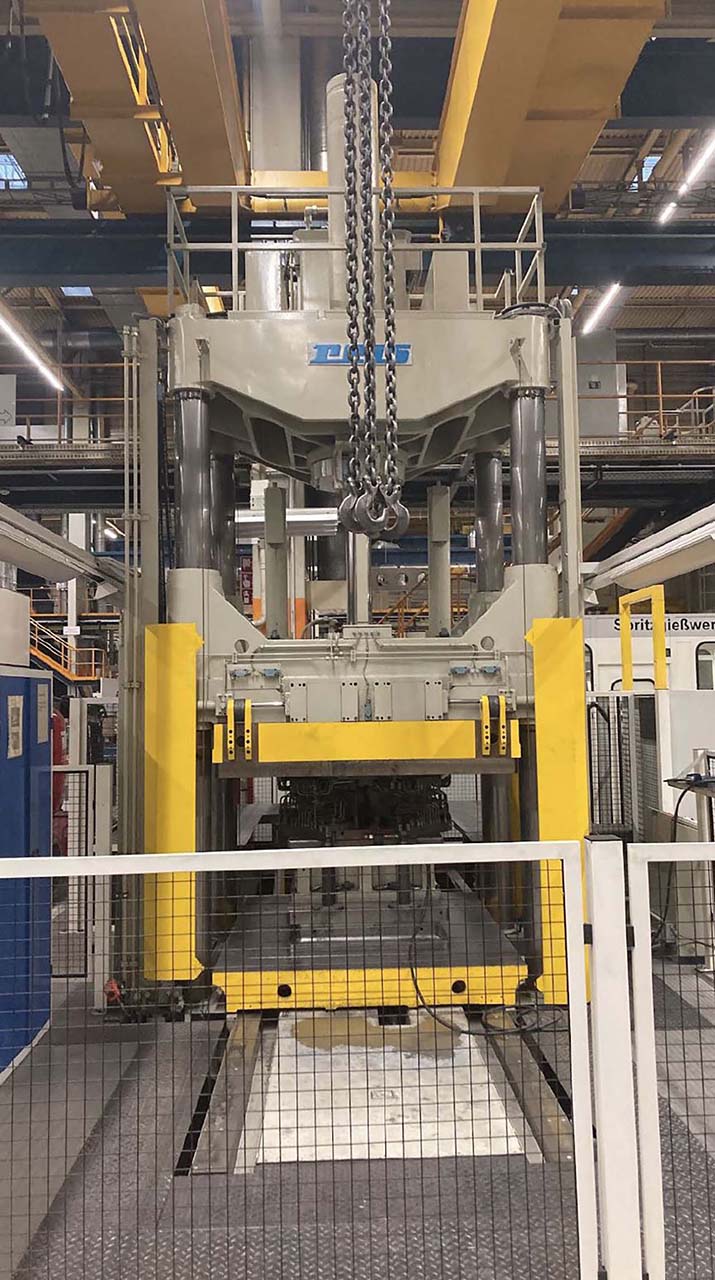

Used hydraulic presses

Hydraulic presses have a particularly high pressing force but a slower stroke than electromechanical presses. This makes them ideal for one-off production or for the individual machining of very thick and resistant workpieces. However, they are also used for series production. Hydraulic presses are used wherever heavy work has to be done. In the car scrap press, for example, hydraulic pressure is used to turn an entire car into a small package of sheet metal. Well-known manufacturers of hydraulic presses are Schuler, Aida, Nidec-Arisa, Simpac, Millutensil, Fagor Arrasate, AP&T, Andritz Kaiser, Presstec Pressentechnologie, Walter Neff, Ebu Umformtechnik, G+K Umformtechnik, Lasco Umformtechnik, Siempelkamp and Müller Weingarten.

Used mechanical presses

Mechanical presses are mostly used for series production. As a rule, the press pressure is sufficient for the desired applications. Electromechanical presses also have the advantage that they can be switched from series stroke to single stroke. In this way, the press stroke can be doubled in order to process even demanding workpieces.

In metalworking, the most diverse types of used presses are used, which fulfil a wide variety of tasks:

- Transferpressen

- Press lines

- Crank presses

- Toggle presses

- Eccentric presses

- Hydraulic presses

- Step presses

- Screw presses

- Punch presses

- Automatic punching presses with strip feeding system and feeding technology

- Forming presses

- Spotting presses

- Trimming presses

- Forging presses for steel and brass

What you should look out for when buying a used press:

Which technical data are relevant?

If you are interested in buying a used press for metal processing, you should first consider what the press will be used for and what technical data it has to fulfil. These can be, for example:

- Cycle times

- Punching force/pressing force

- Pressing and clamping pressure

- workpiece size

- Pressing depth

- Number of strokes/minute

- Energy consumption

- Operating hours

Are you planning series or one-off production?

Hydraulic presses have significantly more power, but usually work too slowly for series production. Mechanical presses work much faster with cycle times of up to one second and are thus perfectly suited for series production.

What are the arguments in favour of presses as used machines?

Presses are an absolute standard tool in the metal industry and are therefore widespread everywhere. However, presses as new machines are basically very expensive. Thanks to the large supply of presses on the second-hand market, attractive offers can be found. From a technical point of view, presses will still be needed in the future and investing in a "good used one" is worthwhile in any case.

With used hydraulic presses, a high age is usually not critical, as they are not used as intensively (as series presses) and reconditioning is not critical. If components need to be replaced, they are easy to obtain on the spare parts market.

Used presses for metal processing and many services from fiss machines for buyers and sellers

The used presses are offered in "as is" condition. We will be pleased to work out an individual proposal for an overhaul or modernisation to suit your budget.

No suitable press? Always ask us, thanks to our contacts we can help you quickly or offer you brand new equipment.