Bühler is a Swiss manufacturer of die casting machines and one of the major suppliers of cold chamber die casting machines. In particular, the production quality of the Bühler machines makes the manufacturer very popular with well-known customers. The manufacturer is, for example, the supplier of VOIT GmbH, which produces the majority of various pressure die castings for the automotive supplier ZF Friedrichshafen.

Cold chamber die casting machines – The Evolution series

With the "Evolution" series Bühler successfully occupies a niche for medium-sized cold chamber die casting machines. With clamping-forces from 2,600 to 9,000 kN, Bühler machines are particularly suitable for complex products, such as gears, pump-parts and electronic-components for motor-vehicles. Despite the large components, tightest tolerances on an Evolution cold chamber die casting machine are continuously guaranteed for all sizes. Fast tool-changes and easy maintenance-intervals provide further increase of the flexibility and operation-periods of the machines.

A cold chamber die casting machine can be ordered in three versions: Lean is the modification of products of low density but high surface-area. Housing-covers are typically products of this version. Compact models include a wide range of standard-manufactured products. This includes all types of mechanical components.

Extended is the execution of a cold chamber die casting machine for heavy, compact and little delicate products. This includes all types of cylindrical or cuboidal products without special shapes.

The continuity of the production quality is guaranteed by the patented Bühler real-time-control. The entire casting process can be controlled precisely with this innovative machine-guide. The results are hardly measurable deviations, even at high output- and fast cycle-rates.

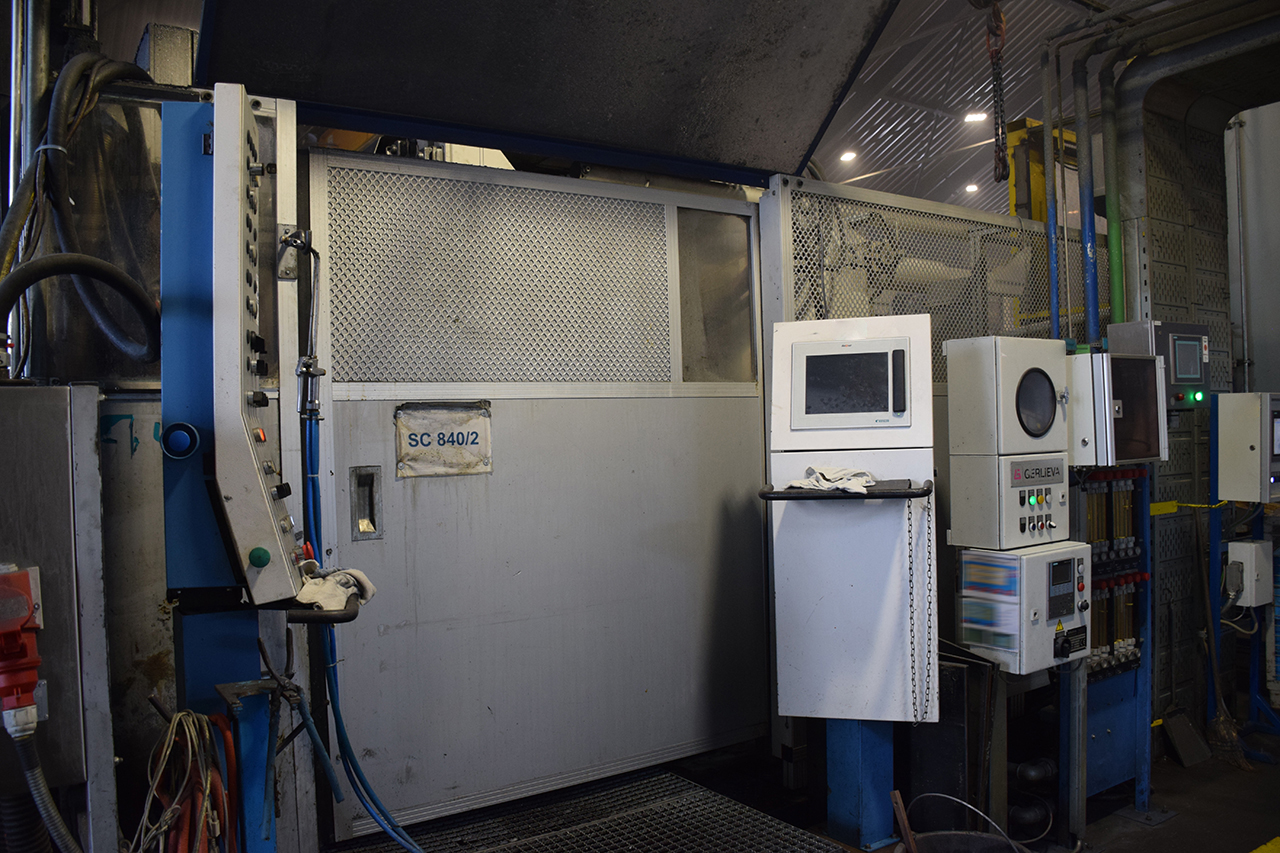

In addition, Bühler pays attention to energy-efficiency and ease of use. The control of the machine is done via the Datanet-cell-control. Touch-panels, networked information-exchange and integrated diagnostic-systems for rapid fault-detection are just three examples of this innovative machine-operation.

We offer: Evolution 26, Evolution 34, Evolution 42, Evolution 53, Evolution 66, Evolution 84, Evolution 90

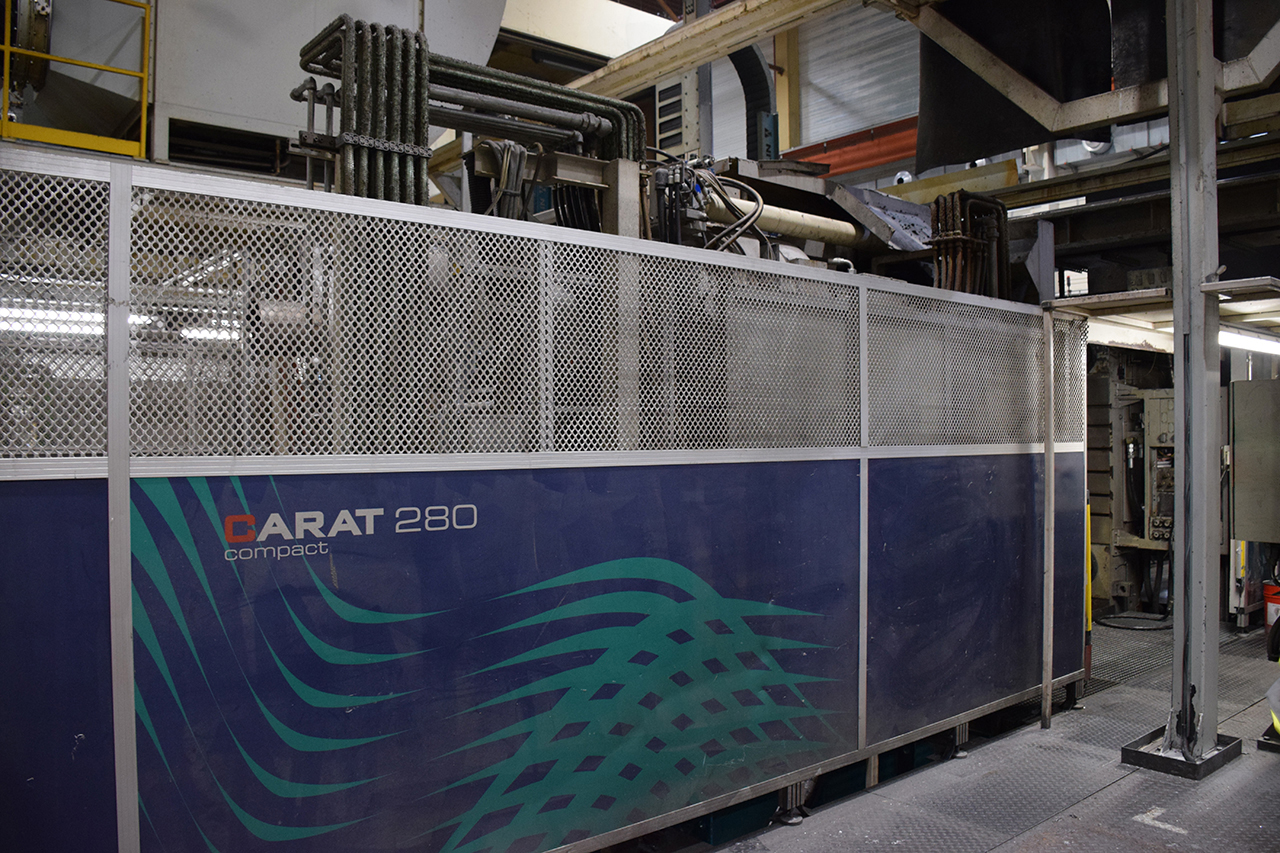

Toggle-free cold chamber die casting machines – The Carat series

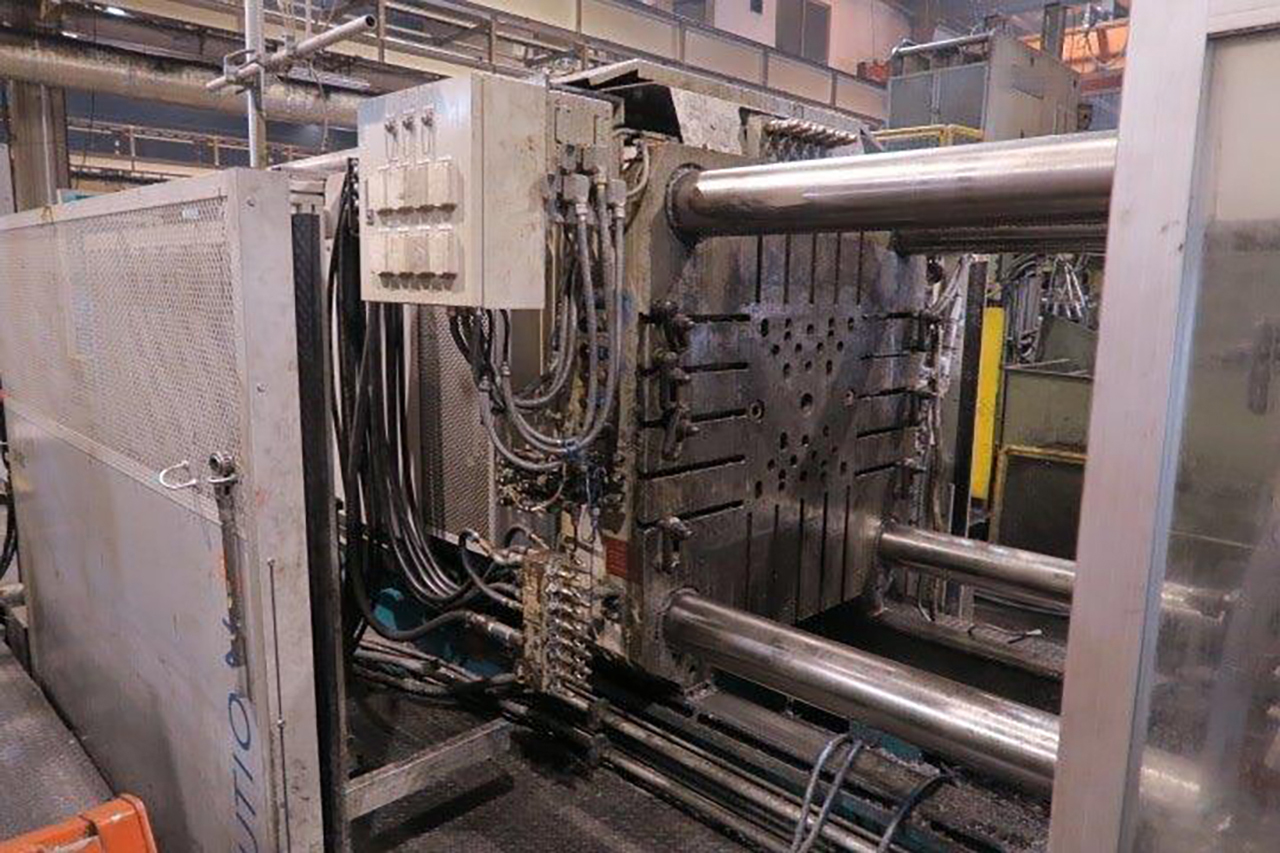

The "Carat" series of Bühler focuses on hydraulic clamping-cylinder instead of the traditional toggle-clamping-mechanism. This process, which is adopted from the plastic-injection-molding, has certain advantages over traditional methods in terms of energy efficiency, accuracy and consistency in product quality. The reduction of moving parts mainly reduces wear and energy consumption.

The "Carat" units are offered with a two-board assembly. There are a total of 13 sizes to choose from. The clamping-force can be gradually increased from 10,500 to 44,000 kN. Consistent quality in the production of large and complex products is the outstanding feature of the Bühler "Carat" die casting machines.

As with the "Evolution" series, the "Carat" machines are offered in the versions Lean, Compact and Extended. The limitation to the two plates increases the stiffness of the machine. Especially for complex parts with close tolerances, a precise design of the casting process is displayed. Bühler offers highest variability in the filling rates of cavities. The design of the casting curves can be precisely controlled. The repeatability of the once programmed casting process is maintained by the real-time control in any number of shots. The casting process thus remains gentle and efficient.

We offer this Toggle-free cold chamber die casting machines: Carat 105, Carat 130, Carat 140, Carat 160, Carat 180, Carat 200, Carat 220, Carat 250, Carat 280, Carat 320, Carat 350, Carat 400, Carat 440

Benefit from full-service at Fiss-machines!

As used machines, systems made by Bühler are excellently suited for the secondary market. The high quality of all components ensures smooth production with the machines over long periods of time.

For this to be ensured, you need a competent partner by your side, who is especially familiar with the dismantling of existing systems and who can offer you a smooth full-service until the assembly at the new location.

We, at Fiss, proved our high level of expertise for more than 30 years on the market and look forward to welcoming you as a satisfied customer.