Kurtz GmbH is a specialist for low-pressure casting machines, gravity casting machines and trimming presses. From single machines to complete casting cells, Kurtz develops individual solutions for the needs of the foundry sector for the automotive industry. Whether chassis or structural part, engine block or housing, Kurtz has the right casting machine for every casting - also as fully automated production units. Kurtz Ersa is a family-owned company with a long tradition. With a global presence and the highest quality standards, the supplier and high-tech group is continuously expanding its position.

Whether low-pressure casting machines, gravity casting machines or trimming presses: Kurtz systems are also highly sought after as used machines in the die casting industry.

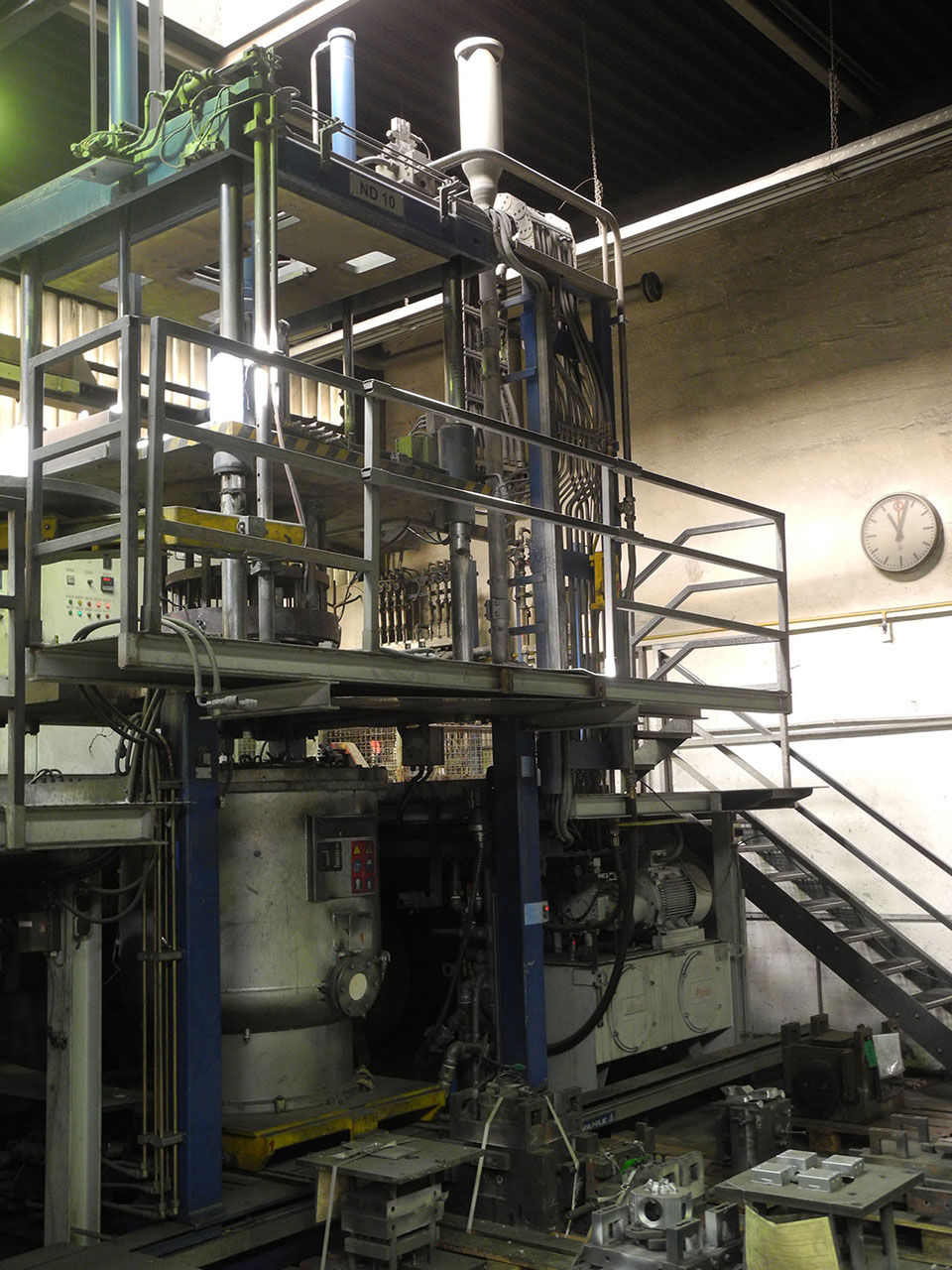

Low pressure die casting machines for low pressure die casting from Kurtz

The range of low pressure die casting machines extends from low pressure die casting with aluminium or magnesium alloy to sophisticated casting in lost moulds. Kurtz Ersa low-pressure casting technology has its own process, which promises high availability, top quality, low scrap and strong competitive advantages.

For example, the FSC model offers an intelligent furnace changeover concept that contributes significantly to the highest machine availability. Kurtz furnace shuttle systems reduce non-productive time and scrap. In this way, energy is also saved while maintaining the best casting quality.

Kurtz currently offers the following low-pressure casting machines: FSC (10-7, 13-13, 16-13, 18-16, 22-17), SC (10-7, 13-13, 16-13, 18-16), TC (10-7, 13-13, 13-13), SR, AL28-18-18FSC, AL18-25C, lost moulds: Sand, lost shapes: Ceramic, lost forms: Plaster

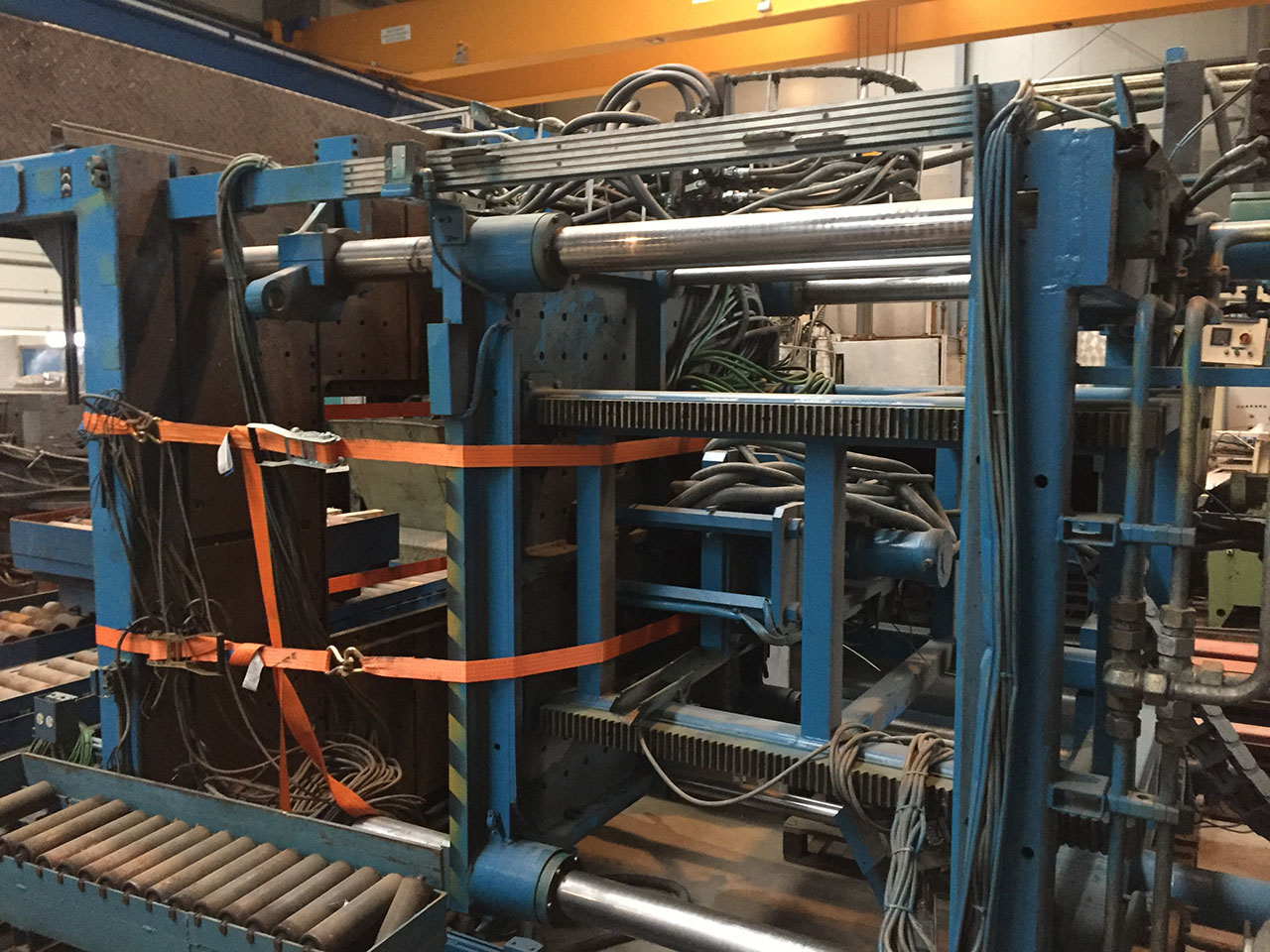

Gravity casting machines from Kurtz Ersa

Gravity casting is THE classic casting method. Known for centuries, it still offers potential for optimisation. Kurtz GmbH has developed a machine concept that can be used universally thanks to its modular design.

Above all, flexibility is demanded by the industry with regard to the most diverse castings. Changeover must be carried out with little effort. Kurtz gravity casting machines meet these requirements without any problems. The basic machine is also suitable for the requirements of highly complex castings by adding core pulls and additional clamping units. Another advantage of all Kurtz gravity casting machines: Thanks to the modular system, clamping units, ejector and core pull units are easily interchangeable. Used gravity casting machines are also popular for gravity die casting.

Deburring presses from Kurtz Ersa

Every casting has burrs and sprues that need to be removed. In addition to the classic, manual "fettling" of castings, there are nowadays automated deburring solutions. An essential component in the deburring technology is the deburring press with tool. Kurtz trimming presses can be found on die-casting machines as well as on gravity, tilting and low-pressure casting machines. Depending on the application, Kurtz offers presses with C-form construction (KPC series, KPC 370, KPC 520, KPC 670, KPC 1000), as column version (KPS series, Kurtz KPS 500) and in frame construction. The new price of a deburring press may be a big financial burden for a company. At Fiss-Machines you can find good used trimming presses from Kurtz.

Buy used casting machines and trimming presses from Kurtz Ersa - only from the experts

In the 30 years of our activity we have gained a lot of experience with machines from Kurtz Ersa and know all strengths as well as possible weak points down to the last detail. Our expert knowledge enables us to make exact statements about the value and maintenance requirements of a used Kurtz machine. We are happy to offer you further services such as disassembly, transport and commissioning of your used machine. We are also happy to overhaul low-pressure casting machines and gravity die casting machines for you! Just contact us, we are there for you!