The company Müller-Weingarten was one of the best known manufacturers of die casting machines in Germany until the year 2011. Especially in the area of the cold chamber die casting machines Müller-Weingarten was able to set accents for decades. The company has always relied on the traditional toggle technology and distributed it to the very end with a great success. This makes the cold chamber die casting machines of this manufacturer an object of desire on the market for used die casting machines. The division of the die casting technology has been taken over by the competitors Frech in 2007.

Attractive prices and a further ensured supply of spare and wear parts by the company Frech make the pressure die casting systems of Müller-Weingarten particularly interesting for the market of used facilities.

Used die casting machines

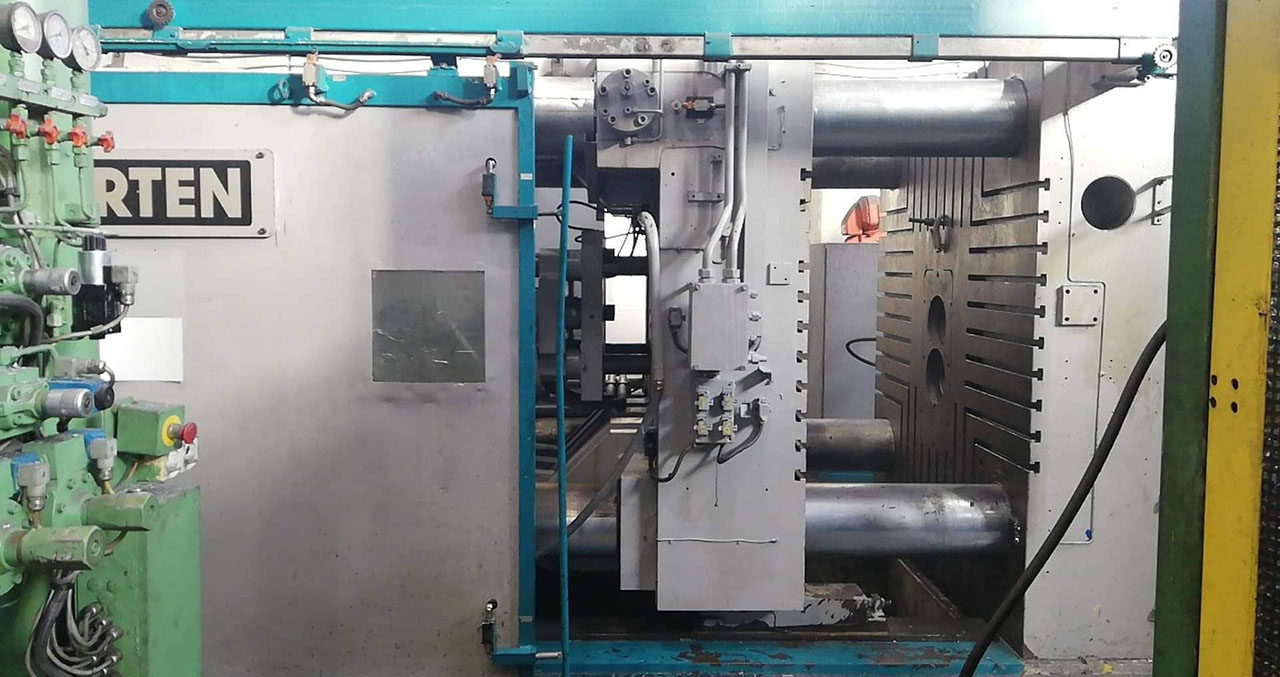

With the model designation GDK a wide range of die casting machines from Müller-Weingarten is still available on the used equipment market. The smallest model is the GDK 125. This machine can score with a remarkable clamping force of 140 tons and a pressing force of 190 kN. With a machine weight about 6.800 kg it is one of the smallest models among the die casting machines indeed. But with its compact dimensions, the GDK 125 can be excellently integrated into a production network. To the largest machine of this class, the GDK 5000, there are 19 different machine types to choose from. Those differ in small stages in size, power and size of tool holders.

We offer: GDK 125, GDK 200, GDK 320, GDK 400, GDK 500, GDK 600, GDK 750, GDK 1000, GDK 1100, GDK 1350, GDK 1600, GDK 2000, GDK 2200, GDK 2500, GDK 2800, GDK 3200, GDK 3500, GDK 4100, GDK 5000

The DualCast series

The DualCast series, which is further successfully sold by Frech today, was an innovation of Müller-Weingarten. The types DualCast 2300, DualCast 2700, DualCast 3200 and DualCast 4000 are also toggle-controlled and equipped with three plates. The die casting machine has not been reinvented with the DualCast series indeed. However, the consistent optimization of all components leads to numerous improvements and an overall higher efficiency.

We offer: DualCast 2300, DualCast 2700, DualCast 3200, DualCast 4000

Benefits of the DualCast-design

- More compact installation area of the machine

- Shortened make-ready times

- Shortened production cycles with constant production weights

- Increased clamping area to retain larger die casting tools

- Flexible supply systems

- New control concept

- Reliable locking function of the mold halves

- Improve of the operating comfort

- User-friendly control system

Buy used die casting machines with the specialist

The modern DualCast models of Müller-Weingarten are already available as used machines today. We, at Fiss, do the assessment, dismantling and reconstruction of the system. Whether you want to buy or sell a Müller-Weingarten die casting machine or a machine from a different manufacturer. Fiss-Machines provides years of experience and excellent expertise.